© Wonders of World Engineering 2014-

Part 6

Part 6 of Wonders of World Engineering was published on Tuesday 6th April 1937, price 7d.

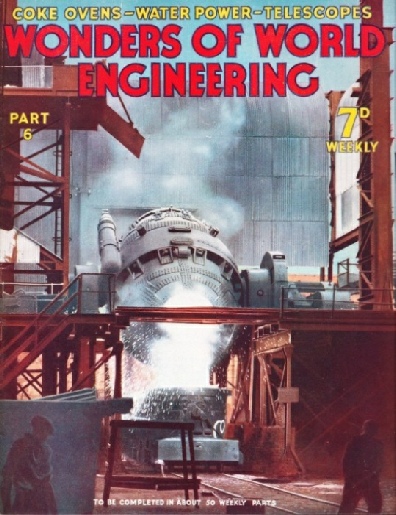

Part 6 includes a colour plate showing Pouring Molten Steel from a Bessemer Converter illustrating the article on Fuel for the Modern Steelworks. The plate also appeared as the front cover of this issue.

The Cover

This week’s cover shows white-hot molten steel being poured from a giant skip into a casting, one of the most impressive sights in a modern steelworks.

Contents of Part 6

Battersea Power Station (Part 2)

The story of Battersea Power Station. The chapter is concluded from part 5.

Germany’s Overland Canal

Instead of using navigational locks, barges on the unique Overland Canal, in East Prussia, are hauled between different levels on wagons running on sets of rails. This article is a two-page photo-feature.

Fuel for the Modern Steelworks

Steel requires, in the making, such large quantities of fuel that the coke ovens of a steelworks are in themselves important examples of engineering practice. These ovens make the coke which is used for smelting the iron ore from which steel is derived. Many people regard coke as prosaic stuff to be used merely to feed the slow combustion stove that heats the bath water. But without coke steel could not be produced. Domestic coke is not the same thing as the coke used in steelworks. The coke that we use in our homes is only a by-product of the gasworks (see the chapter on The Story of Gas Production) and the gas companies are glad to find market for its disposal. When coke is made for steel manufacture it is gas that is the by-product, and after certain substances have been recovered it is sometimes necessary to burn the gas wastefully merely to get rid of it.

Pouring White Hot Steel From a Bessemer Converter (colour plate)

A Bessemer Converter

POURING WHITE HOST STEEL from a Bessemer converter into a ladle for transport to the ingot moulds. The converter is charged with molten pig iron through which air is blown. The air causes the carbon, silicon and other impurities in the iron to burn fiercely so that no fuel is used in the process of conversion. To make pig iron from iron ore, however, large quantities of coke are required and at modern steelworks there is often a battery of ovens continuously at work producing coke from coal.

This colour plate also appeared on the cover of this issue.

Contents of Part 6 (continued)

Power From Scotland’s Lochs

Of all the hydro-electric power schemes in Scotland, the largest and most recent is that in Galloway. Numerous dams, aqueducts, tunnels and other engineering works were built to provide the power for five generating stations which supply current to the Grid. Scotland, with its rivers and lochs, is a greater potential source of water power than any other part of Great Britain. This chapter deals with the vast Galloway Power Scheme in Scotland. This article is the second in the series on the Wonders of Water Power.

Turbine-Driven Locomotive

Although good deal is heard from time to time of the advantages of the electric locomotive, or that deriving its power from a diesel engine, that well-tried servant of the travelling public - the steam locomotive - is not yet superseded or even obsolescent, as recent performances on British main lines have conclusively demonstrated. Recently turbine propulsion has been revived in Sweden, as may be seen in the striking example illustrated in this article. This is the third article in the series describing Modern Engineering Practice.

Giant Telescopes

There are few scientific instruments made to-day which call for such precision in their assembly as modern telescopes. As these instruments may weigh 100 tons or more and have mirrors several tons in weight, their building calls for great engineering skill. Half a century ago the most powerful of telescopes weighed no more than fifteen or twenty tons and had eye-pieces of about 26 in diameter. The largest telescope existing to-day is the 100-in Hooker reflector weighing 96 tons and housed in a circular building on a mountain top in Southern California. A still larger telescope, with a 200-in disk is being prepared for installation about 1940.

The World’s Land Speed Record (Part 1)

Sir Malcolm Campbell's record-breaking Blue Bird cars, in one of which he has attained speeds of more than 300 miles an hour, represent years of careful design and courageous experiment. For ten years Sir Malcolm Campbell tried to achieve a speed of 300 miles an hour. This chapter tells how the record was gradually increased to that figure and of the improvements to the Rolls-Royce engines of the last of the Blue Birds that made such a speed possible. The first men to drive a motor car of any sort were described by many people either as madmen or as criminals; the first designers of motor-car engines were dismissed as visionaries. To these men we owe the modern motor car. What will the motor car of to-morrow owe to the collaboration of drivers such as Malcolm Campbell and engineers such as Blue Bird’s designer, R A Railton? This chapter is concluded in part 7.