© Wonders of World Engineering 2014-

Part 2

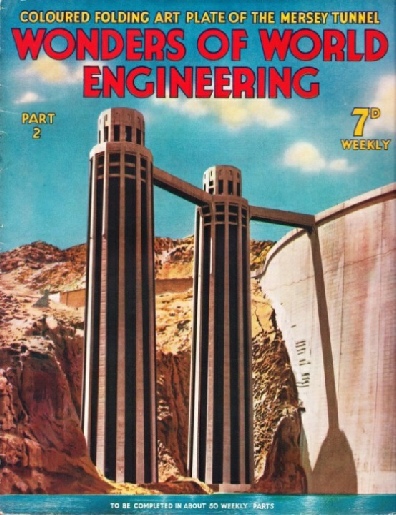

Part 2 of Wonders of World Engineering was published on Tuesday 9th March 1937, price 7d.

Part 2 was a standard issue of 32 pages. The issue included a superb folding colour plate showing a cutaway drawing of the Mersey Tunnel which accompanied an article with the same title. There was also a central photogravure supplement illustrating the article on Building the Boulder Dam. All these are illustrated below.

The Cover

Our cover this week shows two of the intake towers of the Boulder Dam.

Contents of Part 2

The Oil Route from the East (Part 2)

The construction of the pipe line from Kirkuk in Northern Iraq to the ports of Haifa and Tripoli on the Mediterranean coast, concluded from part 1.

The Mersey Tunnel

The design and construction of the Mersey Tunnel. The world's largest underwater tunnel runs beneath the River Mersey for a distance of nearly three miles and joins Liverpool with Birkenhead. It took nine years to build and presented unusual engineering problems. The building of this tunnel is an achievement that represents the concerted energies of thousands of men over a period of years, and the result of their work is an imperishable record of successful achievement. This chapter is the first article in the series Below the Surface.

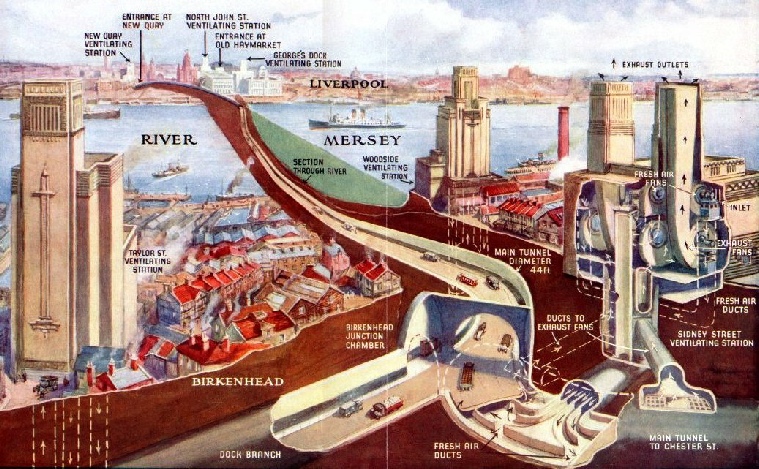

The World’s Largest Underwater Tunnel (colour plate)

The World’s Largest Underwater Tunnel

THE WORLD’S LARGEST UNDERWATER TUNNEL runs beneath the river Mersey between Birkenhead and Liverpool. On either side of the river the tunnel has two entrances, the subsidiary tunnel having an internal diameter of 26 feet. The main tunnel, which has an internal diameter of 44 feet, has a length of 3,751 yards. The width between the kerbs is 36 feet, sufficient for four lines of traffic. The ventilation of this huge tunnel, through which 4,150 vehicles an hour can pass with intervals of 100 feet between them, was a complicated problem. Six enormous ventilating stations were built, three on either side of the rive, to house the gigantic fans.

Contents of Part 2 (continued)

A London Loop Road

A two-page photo-feature on the North Circular. The North Circular Road links the eastern, northern and western suburbs, and enables through traffic to avoid the congested areas of Central London.

Building the Boulder Dam

The flow of the mighty Colorado River has been controlled by the building of one of the world's greatest barrages. The Boulder Dam gave employment to six thousand men for four and a half years. This article begins a new series, Triumphs of Irrigation, a subject that has affected the lives of thousands of people.

Building the Boulder Dam (photogravure supplement)

Contents of Part 2 (continued)

The Story of Gas Production

The manufacture of gas releases valuable by-products of coal which are put to innumerable domestic and commercial uses. Coke, tar, benzole, ammonia and naphtha are among the commodities that are extracted during the distillation of gas from coal. Gas production is one of the most important industries in the world.

Scaling the Ramparts of Brazil (Part 1)

The Sao Paulo Railway, which climbs the Serra do Mar and rises to a height of 2,625 feet in five miles, links the great plateau of Brazil with the South Atlantic Ocean. The cliffs are scaled by one of the most spectacular cable railway systems in the world. The Sao Paulo Railway was a brilliant piece of engineering work, and this article is concluded in part 3.

Building the Boulder Dam:

Photogravure Supplement

THE TASK COMPLETED. While a huge reservoir is forming above the dam, water escapes through twelve valves, six on either side of the canyon, to maintain the steady flow of the river below the dam. This water falls into the river from a height of 180 feet, 13 feet higher than Niagara Falls. At the foot of the dam is the power house, and in the foreground are the openings of the tunnels through which water was diverted while the dam was being built.

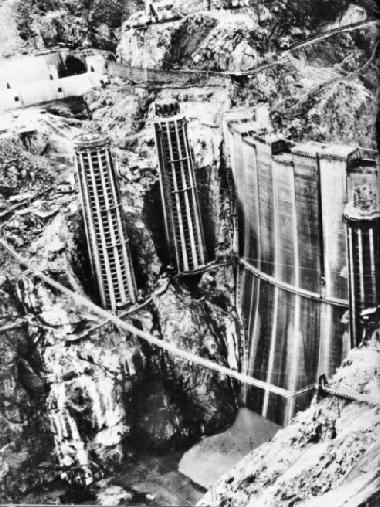

Building the Boulder Dam - 2

THE FOUNDATIONS OF THE DAM were laid 139 feet below the normal water level of the Colorado River, shown by the positions now occupied by the bases of the intake towers (see photo below). Some 3,400,00 cubic yards of concrete were used in the building of the dam, and this enormous volume of material was mixed in two plants near the site of the dam. In the right foreground is the spillway on the Nevada side of the river. The network of specially built roads, bridges and cableways gives some idea of the size of the undertaking.

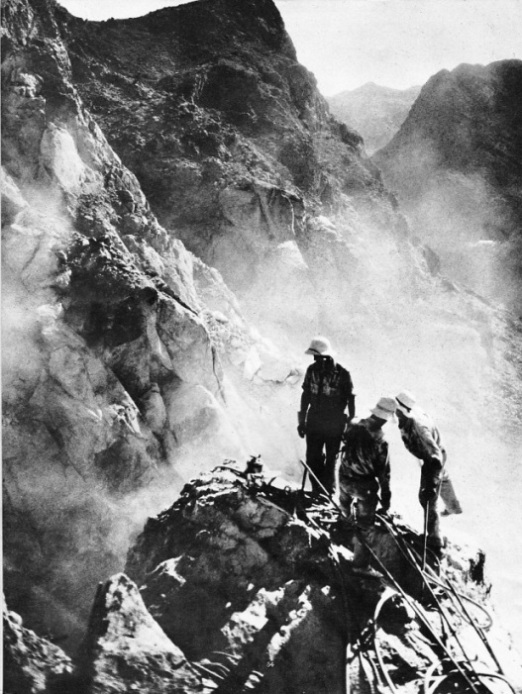

Building the Boulder Dam - 3

SECURING ANCHORAGES from which drillers swung by ropes during the early stages of the work. Hanging hundreds of feet above the river, on the precipitous walls of Black Canyon, gangs of men worked for many months through the terrific heat of summer, drilling, blasting and fixing anchorages for cableways and suspension bridges.