© Wonders of World Engineering 2014-

Part 46

Part 46 of Wonders of World Engineering was published on Tuesday 11th January 1938, price 7d.

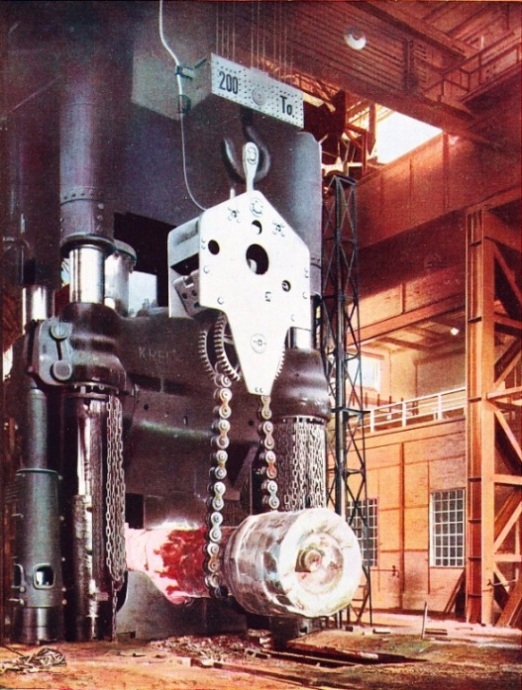

Part 46 includes a colour plate showing a gigantic hydraulic press. It formed part of the article on Steel - From Ingot to Plate .

The colour plate appeared previously as the cover to Part 24.

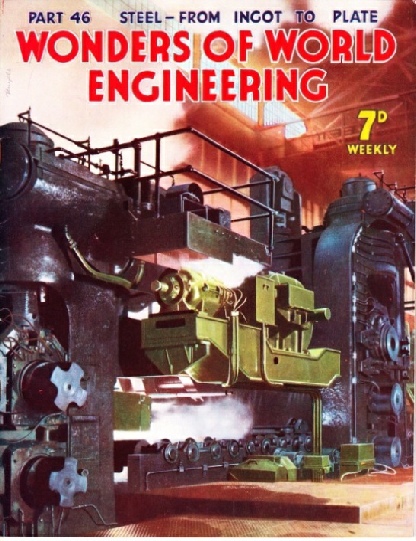

The Cover

The cover this week shows part of one of the most modern steel rolling mills in the United States, that at the Homestead Works of the Carnegie Illinois Steel Corporation. A glowing slab of steel has just passed through the two-high mill on the left, in which the scale has been cracked off; the steel has been turned round before it enters the four-high mill on the right.

Contents of Part 46

The First Atlantic Cable (Part 2)

Manufacture of Pottery

Steel - From Ingot to Plate

A Gigantic Hydraulic Press (colour plate)

Robert Stephenson

The Measurement of Noise

Power Over the Thames

In a Canadian Gold Mine (Part 1)

Manufacture of Pottery

The materials which to to the making of china or earthenware include china clay, china stone, felspar, flint and bone. The bones and flints are calcined and all the ingredients are ground and mixed before they are “thrown” on the potter’s wheel and finished by various processes. The manufacture of pottery is one of the leading industries of Great Britain and it is one of the oldest industries in the world. The best china clay is obtained from Cornwall and Devonshire, and in a later Part of Wonders of World Engineering there is a chapter which describes the methods adopted in the clay mines of Cornwall. This chapter deals with the way in which the engineer has helped the craftsman. An excellent example of this was given in the chapter entitled “Electric Furnaces” one of the illustrations shows an electric furnace specially designed for the treatment of pottery.

This is the fourteenth article in the series on the Romance of Industry.

You can read about Mining for China Clay in part 50.

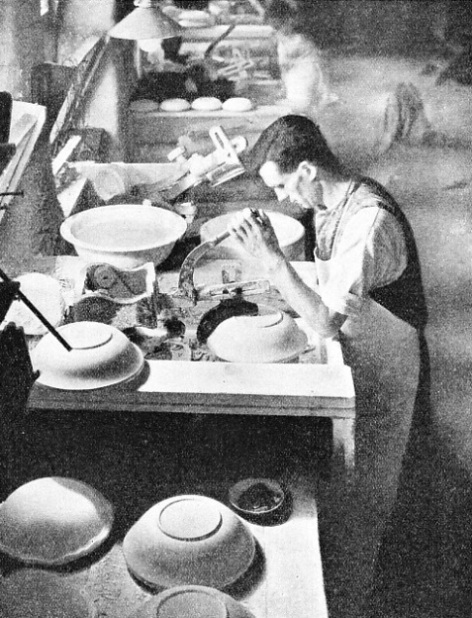

The Jigger

THE JIGGER is the modern counterpart of the potter’s wheel and is used for forming relatively flat articles such as plates and bowls. A vertical revolving spindle carries a mould of the inside of the bowl. When the clay is placed on the revolving mould a pivoted profile of the outside of the bowl is pressed down on the revolving clay.

The First Atlantic Cable (Part 2)

The story of the laying of the first Atlantic cable is an epic of endurance and enterprise. This article is concluded from part 45.

You can read more on Cable Ships, and on The Famous Great Eastern, in Shipping Wonders of the World.

Robert Stephenson

Son of a renowned engineering pioneer, Robert Stephenson adopted a similar career. He helped to establish the locomotive works at Newcastle-on-Tyne , where the famous Rocket was built, and was appointed Engineer to the London and Birmingham Railway. Later he built railway bridges in various parts of the world.

The son of George Stephenson, whose life is described on page 1000, Robert Stephenson followed his father’s footsteps in the world of engineering. His career entitles him also to an important place in the history of engineering.

The son of George Stephenson, whose life is described on page 1000, Robert Stephenson followed his father’s footsteps in the world of engineering. His career entitles him also to an important place in the history of engineering.

Born at Willington Quay, then a mere hamlet about six miles below Newcastle-on-Tyne, on October 16, 1803, the boy may be thought to have had a poor start in life. His mother died in 1806 and his father left him in other hands for a year or so afterwards. This temporary separation, however, did not arise from want of feeling, for few sons could have had more painstaking care bestowed on them during boyhood. The elder Stephenson, mindful of his own ignorant childhood, was determined that young Robert should not be equally handicapped. That the means should be forthcoming to prevent this, the father worked in what spare time he had at shoemaking, cleaning watches and clocks and even at cutting out clothes for the pitmen.

Robert was therefore sent to a good school at Newcastle, cantering there and back daily on a donkey that his father had given him. In the evenings the boy and his father would pore over scientific books borrowed from a library, and the father would carefully instruct his son in that essential art of the engineer - the making and reading of drawings. Robert’s education was not finished here, for after he had left school he spent some years as an apprentice at Killingworth in learning the business of mining. In 1822, his father, at some personal sacrifice, sent the youth to Edinburgh University, for the study of chemistry and physics, at which he proved a diligent and painstaking student. George Stephenson here anticipated a modern form of technical training known as the “sandwich system”.

Robert then assisted his father in the survey for the Stockton and Darlington Railway, and helped with the establishment of the locomotive works at Newcastle which the elder Stephenson and Edward Pease had started. He was next engaged as engineer for some silver mines in Colombia, South America, and thither he went in 1824, to stay until 1827, when he returned to England to assist his father. Before he left Colombia he had an accidental meeting with Richard Trevithick, who had been there since 1816, and was then returning after many discouraging experiences.

Back at Newcastle, Robert Stephenson was concerned with the building of the locomotive Rocket and with other matters connected with the Liverpool and Manchester Railway. In 1830 he was appointed engineer for a line, about sixteen miles long, between Leicester and Swannington. The line presented no great difficulties, but during its construction the young engineer detected signs of coal near Ashby de la Zouch. Its presence being confirmed by his father, the elder Stephenson, with two Liverpool friends, bought an estate on the spot, and sunk a shaft, with satisfactory results to the inhabitants of the town of Leicester; for it enabled them to save about £40,000 a year on their coal purchases, and the cheap coal greatly helped the expansion of local industries.

Robert Stephenson’s next commission was that of Engineer to the London and Birmingham Railway, much of which was to become famous later as part of the London and North Western main line. This line was completed in 1838. It is scarcely possible for the present generation to realize how determined and bitter was the opposition to railways in these early years. At many points the lines had to be diverted to avoid towns which later on demanded diversions and branches to them. This opposition involved the spending of much of the time of the early engineers on attendance at Parliamentary Committees and with other legal business. Some few years later, however, a mania for promoting railways, many entirely unnecessary, developed; but both the Stephensons rigidly declined to have anything to do with these dubious schemes.

Robert Stephenson’s name after a time became identified with the building of railway bridges across waterways - a new science. One of his early works was the fine twenty-eight-arches viaduct at Berwick, built in connexion with the line between Newcastle and Edinburgh. Another was the High Level Bridge at Newcastle, a double-decked structure opened in 1849 and described on page 941. Then came the tubular bridges at Conway and across the Menai Straits. These bridges are described in the chapter beginning on page 125. The type was repeated later on the St. Lawrence River, Canada, and on the River Nile, Egypt, so wide had Robert Stephenson’s practice become.

His advice was sought also for railways in Belgium - where his father was responsible for the first railway - in Sweden, in Switzerland, in Denmark and in other lands. Many professional honours were his, such as the Presidency of the Institution of Civil Engineers, and he served on numerous public bodies. For twelve years he was Member of Parliament for Whitby, Yorkshire, Robert Stephenson survived his father by only eleven years, as he died in 1859. Between the two there had always been strong affection and hearty cooperation. While both were alive each helped the other, but in death they lie far apart, the father in Holy Trinity Church, Chesterfield, and the son by the side of Thomas Telford in Westminster Abbey.

This is the sixteenth article in the series Makers of Engineering History.

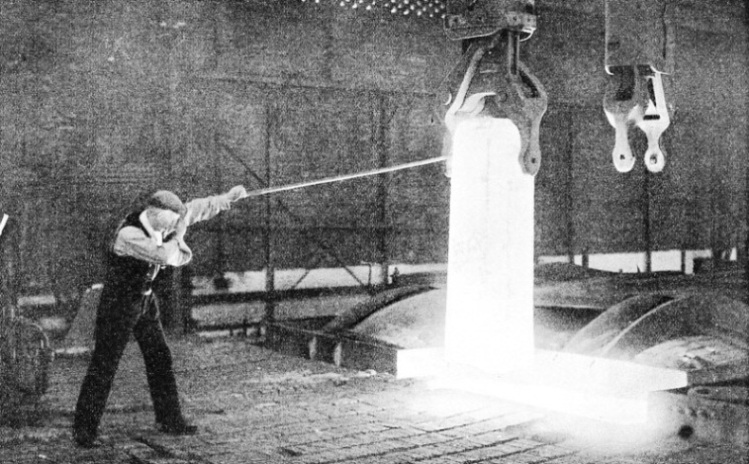

Withdrawing an Ingot from the Soaking Pit

WITHDRAWING AN INGOT from the soaking pit. Ingots when taken from the moulds in which they are cast are hotter in the centre than on the outside and cannot be rolled or forged in this state. They are therefore stored in heated soaking pits for some time until the temperature becomes uniform throughout their mass.

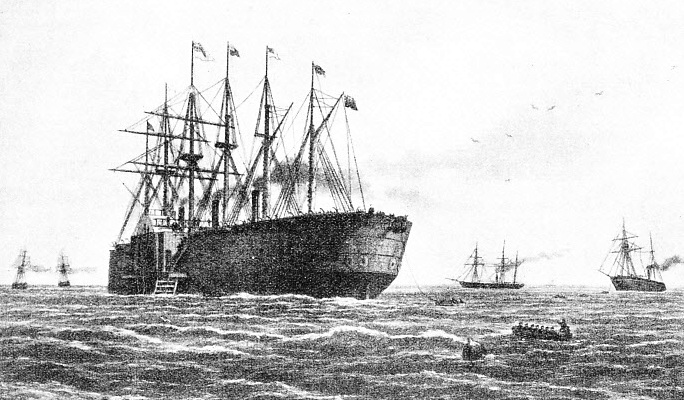

The Great Eastern

ONCE THE LARGEST SHIP IN THE WORLD, the Great Eastern, of 27,384 tons displacement, was used for laying the first successful Atlantic cable. In July 1865 this vessel left Ireland to lay a new cable, but when more than 1,000 miles had been laid the cable parted. In the following year the cable was finally laid.

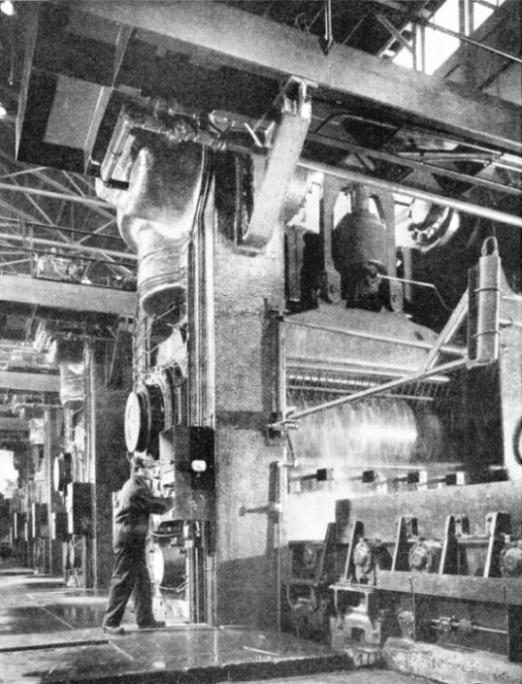

The Finishing Mills at the Homestead Works

THE FINISHING MILLS of the steel rolling plant at the Homestead Works of the Carnegie-Illinois Steel Corporation, in the United States. There are four of these mills, each with four rolls. The hot steel plate passes between the inside pair, which are driven by a motor of 5,000 horse-power. The outside rolls serve as supports to the inside ones. The lowest outside, or backing roll, is not visible. The plates pass successively through all four mills and thence to the roller levelling machine.

The Measurement of Noise

In all branches of industrial activity, in every form of transport and in all fields of engineering steps are being taken to eliminate unwanted noise, which is injurious to health and efficiency. Remarkable devices have been developed to measure the strength and intensity of noises. A great deal of attention has been paid recently to the reduction of noise, which, when excessive, is undoubtedly harmful to health and impairs efficiency. This is of the greatest importance, not only to workers in factories, engineering shops, power stations and the like, but also to every member of the public who travels by train, air or road. The measurement of noise and the values of sound waves form a study of absorbing interest, and many ingenious devices have been developed to measure with great accuracy the intensity of sound.

Traffic Sounds in Berlin

TRAFFIC SOUNDS IN BERLIN being recorded by police officials. The noise of passing vehicles is picked up by the microphone attachment on the kerb and its strength is recorded in phons (units of noise) on the meter on the pavement. This is the objective method. The typical noise level of a loud motor horn is 80 phons, that near concrete drills 110 phons.

Power Over the Thames

The conductors of the Electricity Grid are carried over the River Thames at Dagenham, Essex, by two 487-feet steel towers. The cables had to be raised into position by an ingenious method which caused the least possible interference to the busy river traffic. River crossings must be provided for many things besides transport vehicles and passengers. Pipe lines, aqueducts and power lines, for instance, must be carried either over or under all rivers that lie across their path. Generally these problems are easily solved, but it was no mean task of engineering to carry the power lines of the national Grid System across such a highway of world shipping as the River Thames. At Dagenham, Essex, where the Grid lines cross the River Thames, the river is 2,600 feet wide, and there are no high banks. to give a good clearance. A clearance of 250 feet above high water was necessary so that navigation should not be hampered. The lattice-steel suspension towers on either side of the river are 487 feet high and 3,060 feet apart. Their building and the erection of the conductors is the subject of this chapter.

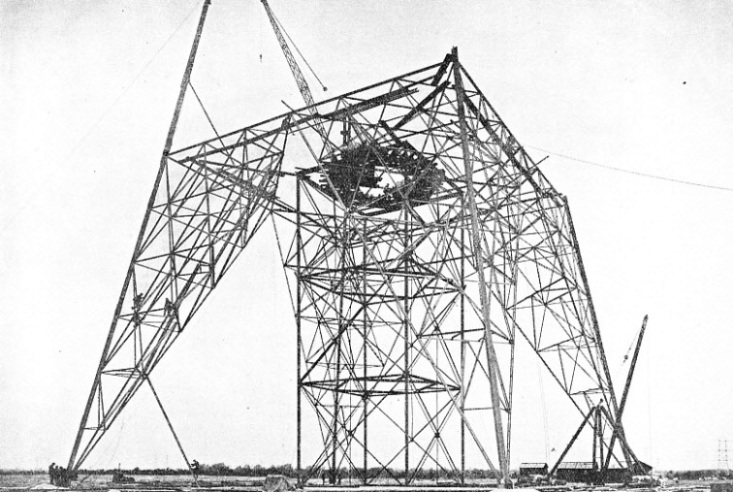

The North Suspension Tower of the Thames Grid Crossing

THE NORTH SUSPENSION TOWER of the Thames grid crossing in an early stage of construction. The steel structure in the centre was temporary, and was built to carry a 3-tons derrick crane which placed the main bracings in position. The tower was built up to a height of some 130 feet by this means. Later, wooden derrick poles were fixed to the main legs and used for hoisting the upper members of the tower.

Steel - From Ingot to Plate

When steel had been cast into an ingot it is in a suitable form for fabrication into steel rails, plate, bars or any form desired. Massive rolling mills produce plate and rails, and powerful hydraulic presses squeeze forgings into shape. This chapter describes steel rolling and forging. In a previous chapter (Part 6) there were described the methods by which ingots of steel are produced from the ore, and this chapter deals with the ways in which the ingots are turned into steel rails, plate and the like. Ingots of white-hot steel, heated to a temperature of more than 2,000 degrees Fahrenheit, are passed through massive rolling mills to be fabricated into the required shape, size and strength. Many machine parts are cast directly from molten steel, but sometimes crankshafts and similar components are forged in massive hydraulic presses.

You can read more about the fabrication of steel rails in Railway Wonders of the World.

A Gigantic Hydraulic Press at Dortmund

GIGANTIC HYDRAULIC PRESS in a steelworks at Dortmund, Germany. The press, which is shaping a huge steel forging, can exert a pressure of 15,000 tons. This method of forging has largely superseded the steam hammer for heavy work. The hydraulic press can handle ingots weighing more than 100 tons.

This colour plate was also reproduced as the cover of Part 24.

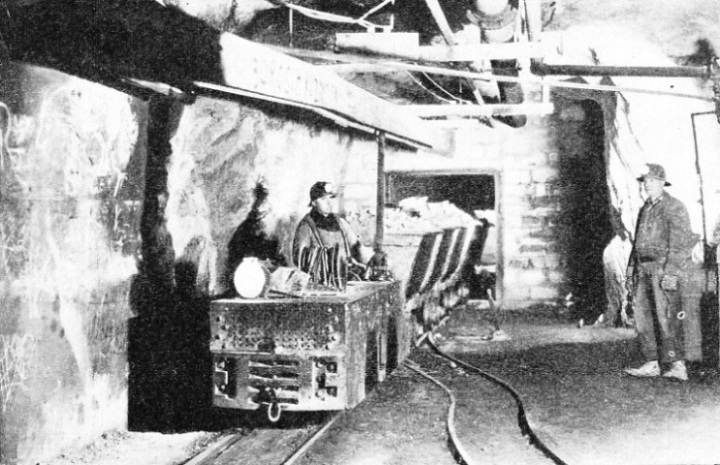

In a Canadian Gold Mine (Part 1)

Gold ore to the value of nearly £60,000 is mined every week in Canada’s largest gold mine. Hollinger Mine, a remarkable example of engineering and one of the world’s greatest producers of gold, rivals the famous mines of the Rand, in South Africa. This chapter describes the Hollinger Gold Mine, Ontario, a great Canadian enterprise which rivals the famous gold mines of South Africa. Last year [1937] this mine produced gold to the value of more than £3,000,000, about 5,000 tons of ore being brought to the surface every day. So rich is the mine that experts have declared that gold probably continues to a depth beyond human reach. Yet it was less than thirty years ago that two prospectors staked their claim to this Canadian El Dorado. The article is concluded in part 47.