© Wonders of World Engineering 2014-

Part 35

Part 35 of Wonders of World Engineering was published on Tuesday 26th October 1937, price 7d.

Part 35 includes a photogravure supplement showing the construction of Liverpool Cathedral. This section illustrates the article on Building a Great Cathedral.

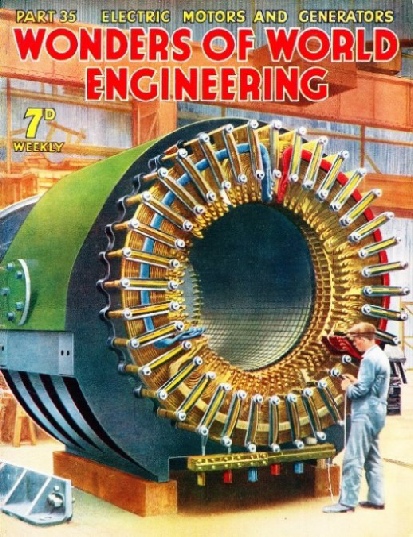

The Cover

The cover of this week’s Part is produced from a photograph supplied by C A Parsons & Co Ltd, of Newcastle-on-Tyne. It shows a huge stator for a 36,000 kilovolt-amps alternator. The development of the turbo-alternator and of other electrical generators is described in this week’s part.

Contents of Part 35

Sweden’s Hydro-Electric Schemes (Part 2)

Describing some of the great modern generating stations of Sweden. The article is concluded from part 34 and is the fourth in the series Wonders of Water Power.

Modern Braking Systems

The evolution of machinery for producing motion in its various forms has necessitated the constant improvement of the brake, upon the efficiency of which the safety of millions of workers and travellers depends. Several chapters of Wonders of World Engineering have dealt with the subject of high speeds in transport, on rail and road, and in the air. This chapter deals with that important corollary of high-speed transport - efficient braking systems. This chapter describes the operation of various types of brake, hydraulic, compressed-air, magnetic and so forth which are used to-day for motor-cars, railway trains and aeroplanes.

George Stephenson

The development of railways came about largely through the enterprise and foresight of George Stephenson, whose engine Locomotion No. 1 was the first in history to haul a trainload of fare-paying passengers. The story of the later life of George Stephenson, the village boy whose unremitting industry brought railways into being, has been written in endless lines of gleaming steel. The history of his earlier years is little known.

This is the twelfth article in the series Makers of Engineering History.

Building a Great Cathedral

Engineering skill is required not only in the building of a great cathedral, but also in the rebuilding or strengthening of many structures which have weakened in the course of centuries. The close association between the engineer and the architect is a noticeable feature of modem building construction. The architect who designs and supervises the building of a modern skyscraper, cinema or store comes in close contact with electrical engineers, sanitary engineers, experts in metallurgy, in physics and in any number of different branches of engineering. Yet the association of the two professions, architecture and engineering, is not altogether a recent development. For instance, they were closely linked in the Roman aqueduct, of which many examples survive in Europe. Many of the works that the medieval builders carried out still stand to-day, timeless monuments to the skill of craftsmen and artists of forgotten ages. In a way, this chapter supplements the chapter which describes the engineer’s part in building the great American skyscrapers.

Building a Great Cathedral (photogravure supplement)

Building a Great Cathedral

Photogravure Supplement - 2

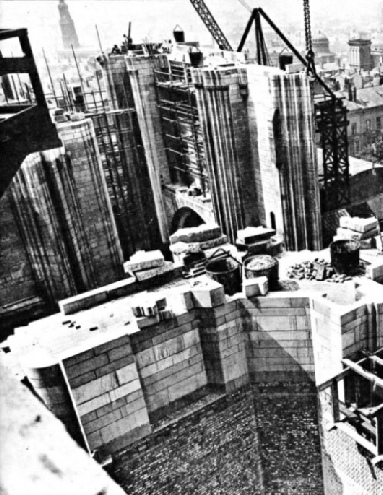

THE WESTERN TRANSEPT of Liverpool Cathedral, seen from the tower. In the left of the photograph is the partly completed wall of the transept. The wall which acts as a buttress to the central tower is 12 feet thick. The width across the transepts is 197 feet. For the transepts and the choir 823,500 cubic feet of stone were used, as well as 6,500,000 bricks and 2,650 tons of cement.

Building a Great Cathedral

Photogravure Supplement

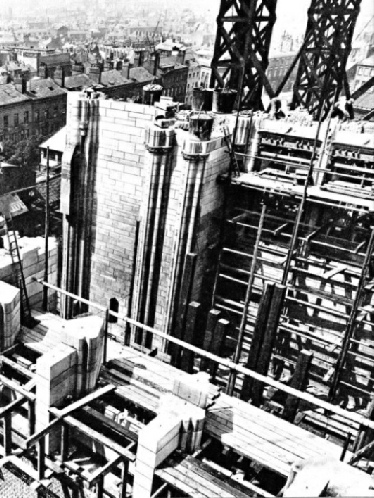

MASSIVE STEELWORK of the tower which carries the ringing chamber and bells of Liverpool Cathedral. This photograph shows the free ends of two of the steel girders. Each girder rests on a cylindrical rocker which ensures that in all conditions of loading the weight is carried on the centre of the bearing. The man seen in the photograph is standing on the concrete girdle upon which the steelwork rests.

Contents of Part 35 (continued)

Electric Motors and Generators

Electrical engineering was founded on the discoveries of Michael Faraday little more than a hundred years ago. The enormous turbo-generators of the modern power station are striking examples of what the electrical engineer ha achieved in a century.

Story of the Cinematograph - 2 (Part 1)

The introduction of the sound film brought about a revolution in the cinema industry, which, although comparatively new, has been developed continuously by the invention of new processes. A later development, the colour film, is now a commercial success. This chapter is concluded in part 36. It is the fourth article in the series Invention and Development.

The first part of the Story of the Cinematograph can be read here.

Building a Great Cathedral

Photogravure Supplement - 3

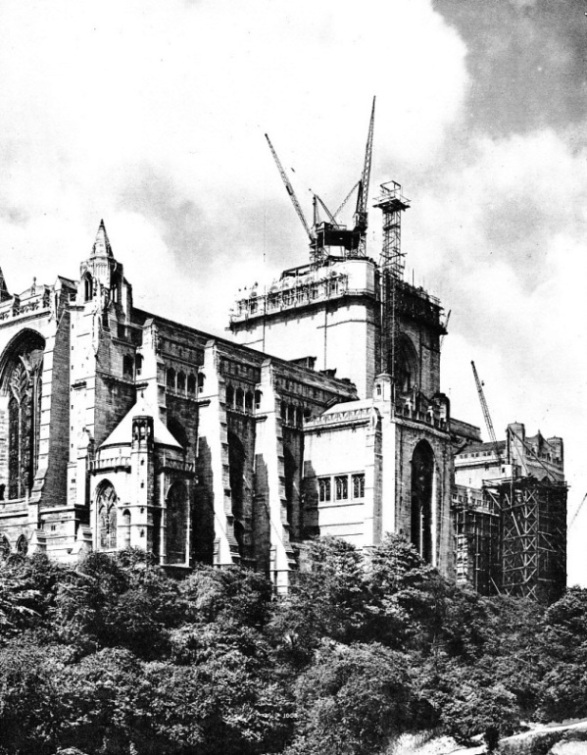

LIVERPOOL CATHEDRAL as seen from the north. The choir is 116 feet high and the inside vaulting of the central tower us 176 ft 6 in above the floor of the cathedral. At a height of 179 feet work was begun on the main tower and belfry. The completed tower will be 97 feet square and will reach a height of 331 feet above the floor. The steel scaffolding on the north face contains an electric lift for the use of workmen on the tower. The twin cranes have a capacity of 3 tons and a radius of 52 feet. The northern arms of the transepts can be seen completed, but the nave, which will be the same size as the choir, is still to be built. The east window, the largest in Great Britain, if not in the world, is 76 feet high and 44 feet wide.