© Wonders of World Engineering 2014-

Part 3

Part 3 of Wonders of World Engineering was published on Tuesday 16th March 1937, price 7d.

Part 3 was a standard issue of 32 pages. It includes a central photogravure supplement illustrating the article Spanning the Firth of Forth.

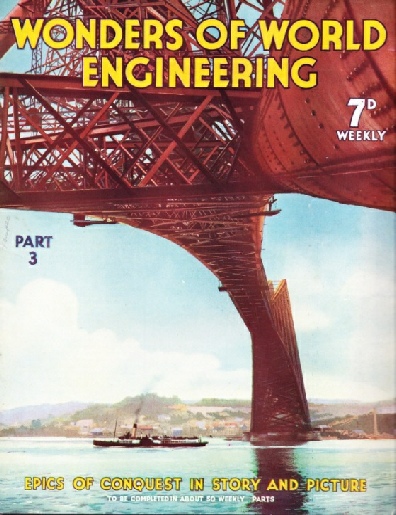

The Cover

The cover of this week’s part gives a striking view of one of the main spans of the Forth Bridge, seen from near the level of the water.

Contents of Part 3

Scaling the Ramparts of Brazil (Part 2)

The story of the Sao Paulo Railway, concluded from part 2.

Britain’s Electric Power Supplies

Electricity has been made available in every part of Great Britain by a national network of transmission lines which link the powerful generating stations with local undertakings all over the country.

Spanning the Firth of Forth

The giant cantilever bridge which spans the Firth of Forth was opened in 1890 and remains one of the wonders of engineering. Built to link the railway systems of the east coast of Scotland, the Forth Bridge has a total length of more than one and a half miles. From the engineer’s point of view the Forth Bridge opened a new era in cantilever construction. This chapter is illustrated with pictures provided with the helpful co-operation of Sir William Arrol & Co. Ltd, the builders of the bridge. This is the second article in the series Linking the World’s Highways.

Spanning the Firth of Forth (photogravure supplement)

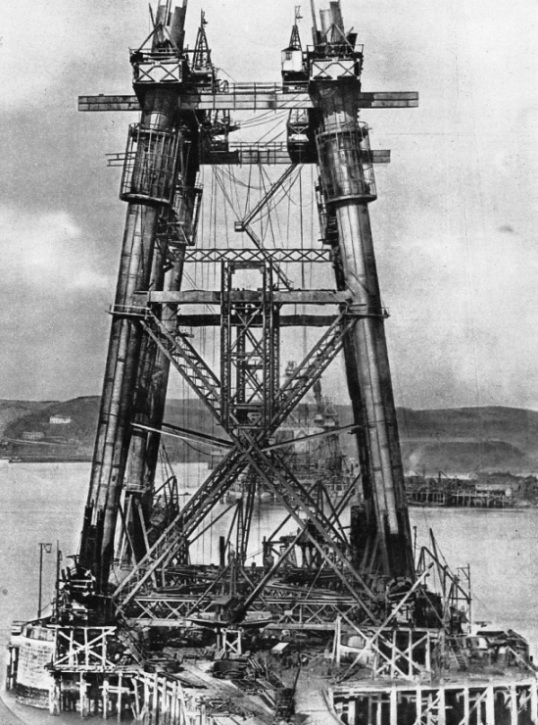

The Forth Bridge: Photogravure Supplement

THE TAPERING "UPRIGHTS" of the central towers, from which the Forth Bridge cantilevers extend, consist of steel tubes, 12 feet in diameter. They taper inwards, from 120 feet apart at the base to only 33 feet apart at the top. The whole structure is held together by a complex arrangement of cross-bracings of lattice steelwork.

Contents of Part 3 (continued)

How Gold is Mined

Modern methods of treating gold-bearing quartz and the scientific separation of gold from impurities have not destroyed the romance always associated with the discovery of gold.

Electric Travelling Crane

Although the jib cranes of the docks or those perched aloft during the building of a steel skyscraper are familiar to many, the more impressive overhead travelling crane seems to be less familiar. Yet without the overhead crane it would be almost impossible to handle the great weights of modern machine parts. An excellent example of modern overhead crane practice is described in this article. This is the first article in a series of one-page articles on Modern Engineering Practice.

Fighting Famine in India (Part 1)

Thousands of miles of canals, bringing water from scores of massive dams and barrages to the arid regions of India, have done much to stamp out famine, the scourge that has caused innumerable deaths. This chapter is the second article in the series on Triumphs of Irrigation. It is concluded in part 4.

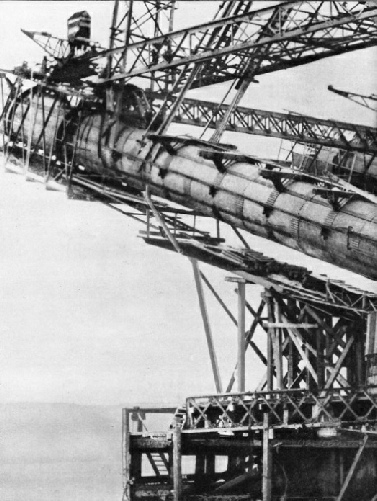

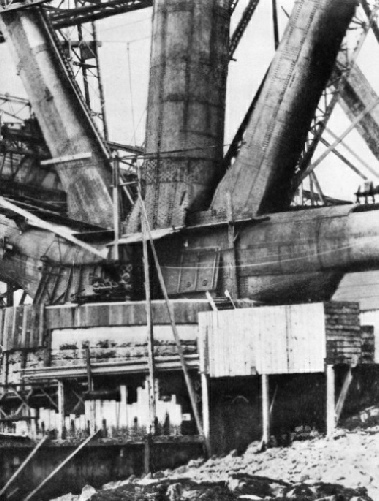

A Cantilever Base on the Forth Bridge

AT THE BASE OF EACH CANTILEVER the “skewbacks” or connexions of the 12-feet tubs, are extremely complicated in arrangement. From the skewback steel tubes, splayed fanwise, extend to the top member of the cantilever, as may be seen in the photograph of the Fife cantilever. The skewbacks of the Forth bridge are more than 40 feet long.

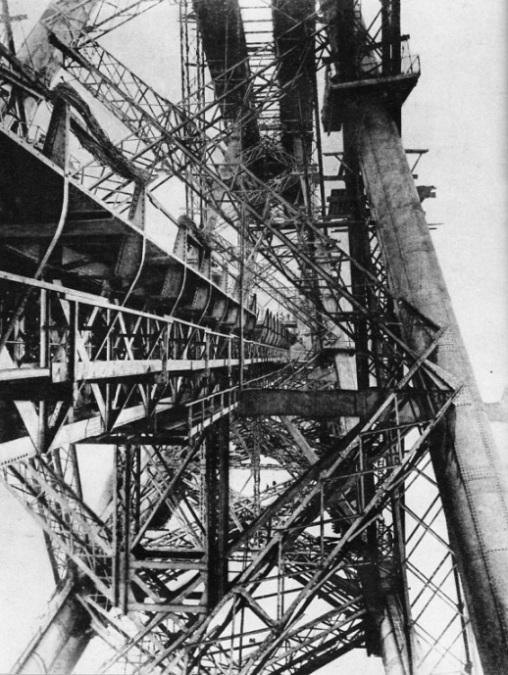

Lattice Girders on the Forth Bridge

A NETWORK OF LATTICE GIRDERS strengthens the cantilevers of the Forth Bridge so that it will withstand a wind pressure of 56 lb. to the square foot. This photograph shows the lattice steelwork in a cantilever at rail level.