© Wonders of World Engineering 2014-

Part 15

Part 15 of Wonders of World Engineering was published on Tuesday 8th June 1937, price 7d.

Part 15 includes a photogravure supplement showing the Romance of African Copper, which illustrates the article on this subject.

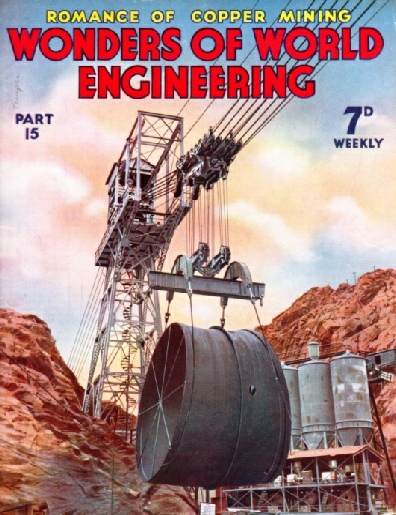

The Cover

The cover this week’s Part gives a striking view of one of the cableways used for transporting material during the building of the Boulder Dam, which was described in an earlier chapter.

Contents of Part 15

Tunnelling the Hudson (Part 2)

The story of the thirty year struggle to complete the Hudson Tunnel beneath the Hudson River, New York. The chapter is concluded from part 14. This is the third article in the series Below the Surface.

The Craft of the Welder

Modern industrial welding is a constructional method practised in workshops all over the world. Three principal welding systems are in use, the electric, the oxy-gas and the thermit process. Electric welding may call for temperatures as high as 7,500 degrees Fahrenheit. This chapter is full of interesting explanations of the various welding processes that are used.

Lifting Span and Swing Bridges

THE task of building a bridge or viaduct across a waterway frequented by small craft only is generally much easier for the engineer than when the waterway is used by large ships. This chapter describes the principles of vertical lift bridges and of swing span bridges. This is the eighth article in the series on Modern Engineering Practice.

Romance of African Copper

The riches of the Copper Belt in Katanga, Belgian Congo, and of the copper mines in Northern Rhodesia have been won by the efforts of explorers, railway pioneers and mining engineers, who have built up an important industry in a district remote from the rest of civilization. One of the richest copper-bearing districts in the world is the Katanga Copper belt in the Belgian Congo. Here are numbers of rich copper mines, and this chapter describes how the copper is extracted from the ore in the African mines.

Romance of African Copper (photogravure supplement)

Romance of African Copper:

Photogravure Supplement

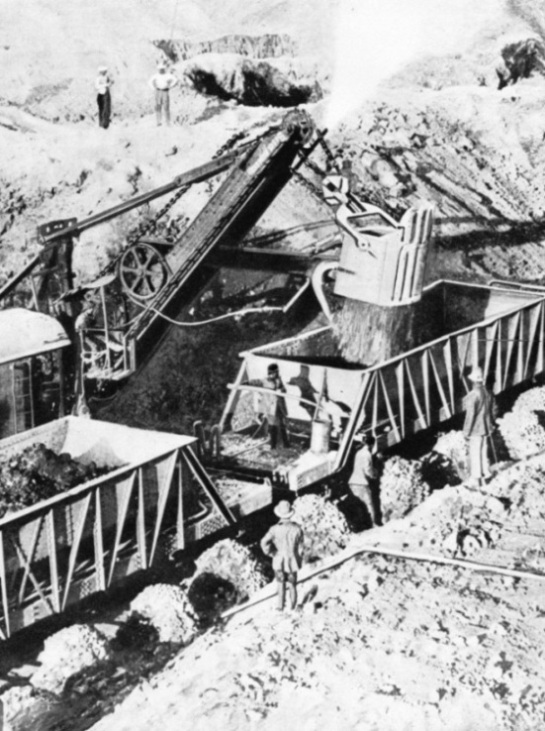

IN OPEN MINES, where copper-bearing ores are near the surface, steam shovels load the ore into railway trucks. The trucks are then hauled to the crushing plant where the ore is crushed and ground to a fine powder before treatment for the extraction of the copper.

Contents of Part 15 (continued)

Building Dover Harbour

The exposed position of Dover made the building of its huge naval harbour a tremendous feat of engineering, calling for much daring and high organizing skill. One of the largest, and certainly one of the most important examples of harbour building is the National Harbour at Dover. Eleven years were occupied in this work, and the cost of it was about £4,000,000. In all about two and a half miles of breakwater and sea wall were built. The work is described in this chapter. The harbour was opened on October 15, 1909. There is accommodation, in the enclosed water area of 610 acres, for a fleet of large warships and their attendant craft.

The Trans-Siberian Route (Part 1)

Despite enormous difficulties imposed by the nature of the country, which included steppes, rivers, lakes, mountains and desert, engineers at last succeeded in linking East and West with a steel highway across the largest stretch of unbroken land in the world. This article is Railway Engineers at Work.

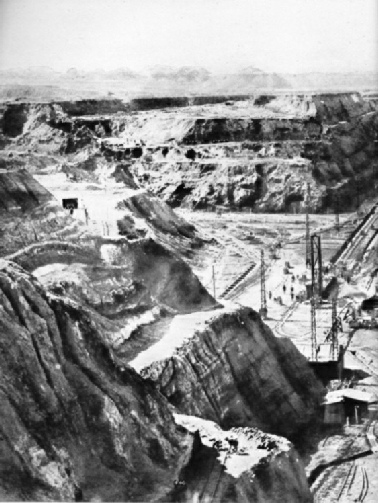

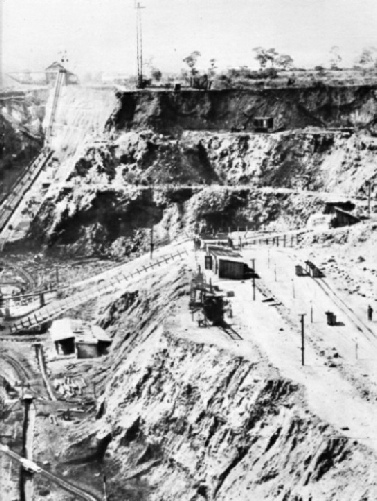

The Ruashi Copper Mine

A LARGE OPEN COPPER MINE in the Belgian Congo. The Ruashi Mine, which is not far from the “Star of the Congo” and Elisabethville, was opened in 1922. This mine is an excellent example of the system of open working used when the copper ores are to be found near the surface. When the ores are at a greater depth shafts have to be sunk.

Romance of African Copper:

Photogravure Supplement

3

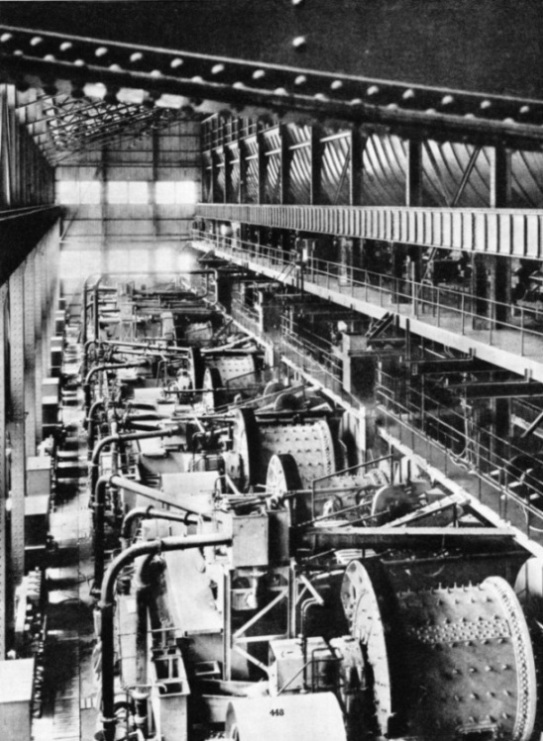

THE CONCENTRATOR PLANT at the N’Kana Mine, in Northern Rhodesia. The ore is first crushed to a powder and is then put in a vat of water. The water is agitated and a frothing oil is added. A film of oil adheres to the particles of copper and air bubbles form on the copper, causing it to float to the surface and leave the worthless matter suspended in the water.