© Wonders of World Engineering 2014-

The central span of the Fades Viaduct is 20 feet higher than the topmost point of the Forth Bridge

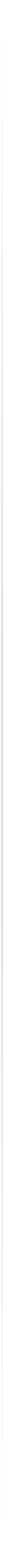

THE FADES VIADUCT ACROSS THE SIOULE RIVER, PUY-DE-DOME, FRANCE

WHILE it is always somewhat hazardous to award the palm of distinction to any particular undertaking in the field of engineering, it is probable that pride of place in bridge building, so far as height combined with length is concerned, is occupied by the Fades Viaduct, which spans the wide, deep, verdant gorge through which flows the Sioule River, below St. Eloy, in the province of Puy-de-Dôme, France. It is undoubtedly a meritorious work, rivalling even the masterpiece of Monsieur G. Eiffel at Garabit, not far distant. Although not quite so long as the last-named structure, the level of the railway metals is over 30 feet higher. If the Fades Viaduct were planted across the Firth of Forth, the towers of Sir Benjamin Baker’s huge cantilever structure might be placed comfortably beneath its central span, and yet leave 20 feet head room.

The urgency of this undertaking had been maintained for many years in order to complete the Tulle-Clermont and Montluçon-Gannat railway. But the Sioule River offered an insurmountable obstacle. The ravine is a huge deep V in the rugged centre of France, the banks sloping down at an angle of some 45 degrees to the river at the bottom, while the distance across the gap at the top exceeds ¼ mile. Investigations proved that the only means of negotiating this interruption was by connecting the upper points of the V, it being impossible to carry the line down the valley slopes to cross at a lower level.

A wide variety of competitive designs for a bridge were prepared and submitted to the authorities. After careful investigation the proposal of M. Draux, the Government engineer, found favour in Ministerial eyes. The successful engineer when submitting his ideas was careful to emphasise that the difficulties of erection would be abnormal, and that new, untried methods would have to be called into service, the success of which, from lack of experience under similar conditions, was uncertain. The issue became complicated, because during the examination of the various designs other unexpected problems came to light, so that the whole question had to be threshed out anew.

Considerable delay thus arose. Repeated adjurations were made to commence the work, but the authorities refused to be hurried, in view of the magnitude of the enterprise. There must be no possibility of failure; no cessation of work when once started, through the “unexpected” suddenly revealing itself; and, above all, absolute safety must be assured. Every contingency

that might crop up was considered and due provision made therefor.

When official approval was extended at last, the designs provided for a bridge with a total length of 1,526 feet divided into four spans. The outstanding feature was the main span above the waterway and its massive masonry piers.

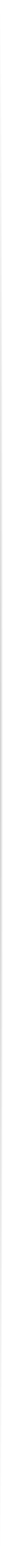

COMMENCING THE STEELWORK ON ONE OF THE SHORE SPANS: SHOWING THE WIRE-NETTING ENCLOSED TRAVELLER

The first move was the preparation of the masonry work, and troubles were experienced almost at the beginning. On the St. Eloy side of the valley the contractor carried his excavations down to a depth of 23 feet to secure foundations for the abutment, but failed to discover anything better than badly cracked rock. Instead of driving more deeply in the hope of finding firmer ground, he started to lay his foundations upon this broken surface, endeavouring to secure homogeneity by introducing a system of interlocked steel bars. The masonry had been carried up to a height of 98 feet when labour was stopped suddenly. The whole mass was sliding downwards into the valley! This was quite an unexpected development. The engineers hurriedly made a number of borings to discover the cause of this mishap, and found that the subsoil was absolutely unsafe. Without further ado the whole of the masonry was demolished and its use abandoned in favour of a short steel span.

At this juncture the masonry contractor died, and the whole undertaking was suddenly thrust upon the famous Société Française de Constructions Mécaniques - formerly the Cail Company - of Denain, who had been awarded the contract for the steelwork only. Upon arrival at the site the first question was the establishment of temporary communication between the opposite sides of the valley, to facilitate the movement of the constructional material and men. A small incline railway was laid down each slope and connected at the bottom by means of a wooden bridge across the river. In this way it was possible to pass from the brink of one bank to that of the other in a few seconds, thereby avoiding the tedious toil along the highway which zigzags down the valley sides. An electric generating station was established with the dynamos driven by motors fed with producer gas, since electric energy was used throughout for driving sand-mills, mortar-mixers, lifting gear, and a hundred and one other operations.

The most important and difficult part of the undertaking was in connection with the main span, 472½ feet in length, which lies immediately above the River Sioule. When one stands on the rails in the centre of this span, the water flows 434 ft. 8½ in. below one’s feet. This central mass of steel is supported at each end upon a huge masonry pier. These piers are of rectangular shape, with the longest sides parallel with the river. They rise in scarcely perceptible curves to the top, which gives them a graceful, substantial appearance.

The erection of the piers proved somewhat costly owing to their dimensions. Each rests upon a solid massive plinth carried deeply down to the solid rock. At the base they measure 72 feet in length by 38 feet wide, and rise to a height of 302 ft. 4 in. above the foundations, tapering gradually to 36 feet by 18 feet at the top, where they are finished tastefully with a decorative stone coping, projecting 3 feet from the face of the towers.

Construction was carried out from the inside, thereby dispensing with elaborate external scaffolding. A shaft extends from top to ground level, and this vertical passage constructed, was used by workmen and also for the conveyance of the building material. The latter upon reaching the building level was handled by a small derrick which lowered it where it was required. Granite was used exclusively, although it had to be brought from a quarry some 10 miles away, while it was subjected to elaborate tests to ensure the stipulated quality. Small cubes of the stone, measuring 2 inches, representing the material for the inner lining, were submitted to crushing, and were found to resist a pressure of 7,865 pounds per square inch, while the granite selected for facing and the decorative coping resisted a pressure of 8,840 pounds per square inch.

Owing to the diminishing sectional area of the towers as they rose upward, the space upon which the masons toiled grew more cramped every day. When the last course of stones was set in position the labourers were almost on a level with the tableland on either hand. Then a heavy cradle was rigged up to encircle each pier, and swung from the corners of the tower tops. This was lowered, with a small gang on board, who pointed and applied other finishing touches to the stonework facing, being hauled up and down from their working level on the swinging platform, which was caged in to protect the men from falling. By the time these two lofty piers were completed £52,000 had been expended, while the total cost of all the earthwork and masonry for the structure was £98,000.

Owing to the diminishing sectional area of the towers as they rose upward, the space upon which the masons toiled grew more cramped every day. When the last course of stones was set in position the labourers were almost on a level with the tableland on either hand. Then a heavy cradle was rigged up to encircle each pier, and swung from the corners of the tower tops. This was lowered, with a small gang on board, who pointed and applied other finishing touches to the stonework facing, being hauled up and down from their working level on the swinging platform, which was caged in to protect the men from falling. By the time these two lofty piers were completed £52,000 had been expended, while the total cost of all the earthwork and masonry for the structure was £98,000.

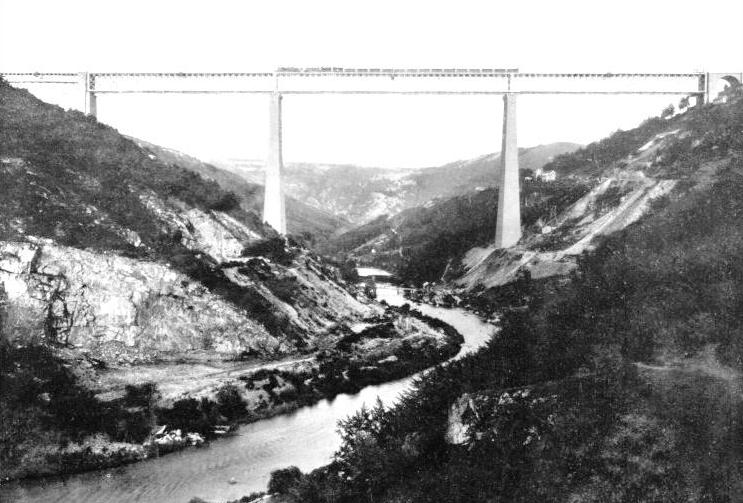

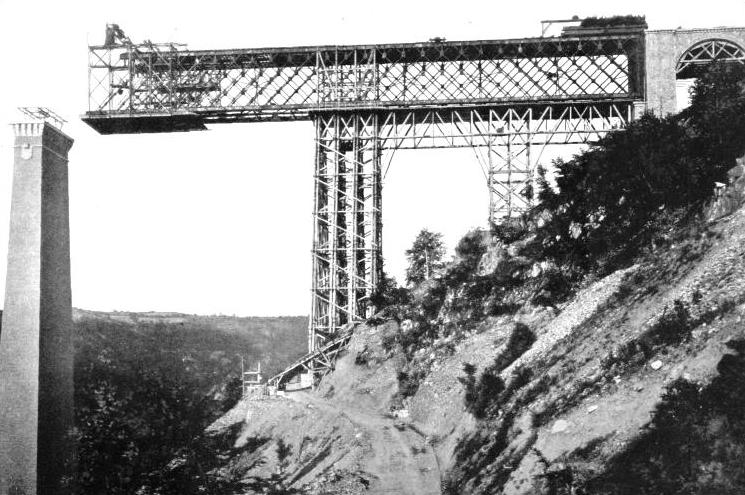

THE FIRST COMPLETE SPAN OF THE FADES VIADUCT

The view shows the engineers’ inclined railway down the valley side

As the towers approached completion preparations for setting the steelwork were advanced. The shore span of 380 feet springing from the Pauniat side was taken in hand first, in 1904. When it was decided to erect the lofty masonry piers, serious objections were raised in certain quarters that high winds would set up heavy oscillation - that they would sway to and fro in the same manner as tall factory chimneys and other similar structures respond to the pressure of the winds. The engineers, however, who had studied the wind velocities minutely, replied that they had so designed their work as to balance any such stresses that could be brought to bear upon it, and with a good margin to spare. Moreover, they maintained, once the steelwork was in position, that the whole fabric would be braced together and be rendered as rigid and solid as a rock.

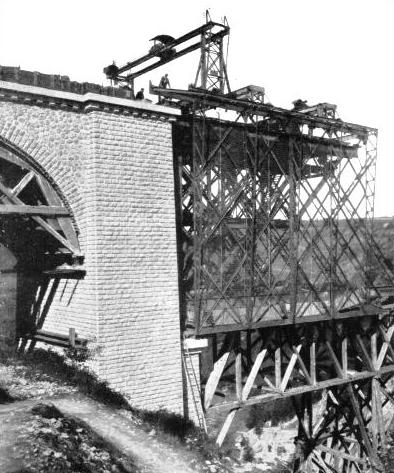

The first half of the shore section was built upon a heavy timber falsework. When the steel reached the outer edge of this timbering it was continued over the intermediate gap of 190 feet to the top of the first main pier. To counterbalance the increasing weight of this overhanging section a huge counterweight of steel rails was placed upon the part of the span

already completed at the shore end. The steelwork, comprising a rectangular structure measuring 22¾ feet wide by 40 feet in height, built up of two main side-latticework trusses, was erected upon lines evolved by M. Cartier, one of the engineers to the Cail Company. There was a large cage, which slipped over the end of the truss. This was fitted with rollers, which ran along the top girders, so that the cage could be pushed forward as the steelwork crept outwards. In order to extend complete protection to the workmen this traveller was enclosed in network to the top of the sides, while the floor was solid. Consequently, if a workman missed his footing he was saved from certain death. Similarly the loss of tools was obviated, as they could be recovered easily.

On the top side of this cage a small overhead travelling electric-driven crane was mounted. As it was able to move over the full length and width of the metallic work, this appliance commanded the whole working area, so that the heavy pieces of steel were lowered into position easily, while the cumbrous tools by which the sections were riveted up were similarly moved from point to point as desired. After the Pauniat shore span was completed to the first pier, the timber falsework was taken down, transferred by the incline railways to the St. Eloy bank, where the shore span, of identical length on that side, was set in position in a similar manner.

The completion of these respective shore spans left the long gap, 472½ feet in width, over the river to be bridged. This was the most difficult and hazardous part of the whole undertaking. No timber falsework was possible here. Instead, the section had to be built on the overhang method. An erection cage, which with its overhead equipment weighed about 80 tons, advanced boldly into mid-air from each tower to meet immediately above the centre of the Sioule River. Care was observed to maintain the same rate of advance from each side, so that the two cages might reach the centre simultaneously. Erection was accomplished fairly quickly, the steelwork creeping forward through the air at the rate of 4¼ feet per day from each arm, making a total advance of 8½ feet per day. When the centre of the gap was almost reached a small footbridge was thrown from arm to arm, affording communication between the advancing trusses, and, when at last the two cages met, they were bolted together, and preparations made to join the two sections of the span together.

THE TIMBER FALSEWORK FOR ERECTING ONE-HALF OF A SHORE SPAN

The connection of two such immense steel limbs in mid-air is a delicate operation demanding extreme care; the two extremities had to be brought dead in line, both horizontally and vertically. The weight of the overhanging sections had caused the two extremities to sag about 13 inches. This defect had first to be corrected, and any possible lateral deviation provided for. This was accomplished by the aid of hydraulic jacks, which were set beneath the span on the main piers, and also beneath the ends of the steelwork on the bank abutments. As the weight of steel to be moved represented about 1,200 tons, four jacks, each capable of lifting 300 tons, were placed on the piers in such a manner that the entire arms of steel could be moved sideways as well as up and down. By lifting the whole mass of steel on the main piers and lowering the jacks on the abutments, the end of each limb of steel was canted upwards until the deflected extremities were dead in line.

In such work as this the temperature of the atmosphere plays a very vital part in the final operation. The expansion and contraction of such a long mass of steelwork under the fluctuations in the heat of the sun’s rays is appreciable. As the Fades Viaduct lies across the gorge in a north by south direction the sun plays only on one side of the structure at a time, so that expansion is unequal. This fact demanded skilful treatment. The closing operation took place on May 17th, 1909. The east side was closed when the sun was shining brightly. When the girders forming the chord were lowered into position it was found that the 1-inch rivet holes therein came flush with the relative holes in the fixed part of the bridge. Accordingly bolts were slipped in and the breach on that side closed speedily. On the west side, as it was in the shade at the time, the holes in the closing girder and the ends of the arms were out by 5/16 inch. Consequently a temporary closure was made on this side by driving home 9/16 inch bolts. At a later hour, when, under the influence of the sun’s rays the west side of the bridge expanded, the temporary bolts were withdrawn, as the holes came accurately together to permit the 1-inch rivets to be driven home. The jacks on the main piers afterwards were lowered, so that the steelwork came to rest in its normal position upon the expansion rollers.

CRAWLING FOOT BY FOOT TOWARDS THE FIRST PIER.

Showing timber falsework for half the distance, and counterweight at shore end to counterbalance weight of overhanging section.

Owing to the elaborate precautions adopted, only one life was lost over this great work, and this occurred during painting operations. The bridge carries a single railway track of standard gauge on the top deck. Special arrangements have been introduced to prevent a train, in the event of derailment, plunging over the side into the depths of the valley. The bridge has been designed so as to be able to withstand any load that might be brought to bear upon it even under the most disadvantageous circumstances. On the upper deck there is a narrow footway, level with the metals, to facilitate the inspection of the permanent way, while a footbridge, 3 feet wide, is fitted to the bottom girders for the purposes of inspecting, repairing, and painting the bridge.

The Fades Viaduct is one of the most impressive works of its kind in the world, and commands attention on account of its great height. There can be no question that it serves as an imposing record of the skill of the French bridge builders. It was a highly responsible undertaking, and some eight years were occupied in its fulfilment. After being tested it was taken over by the Paris-Orleans Railway Company in September, 1909.

GENERAL VIEW OF THE SIOULE RIVER VALLEY AND THE VIADUCT WORKS. SHOWING THE TWO CHIMNEY-LIKE PIERS

You can read more on “The Eiffel Tower”, “Spanning the Firth of Forth” and “The Story of the Tay Bridges” on this website.