© Wonders of World Engineering 2014-

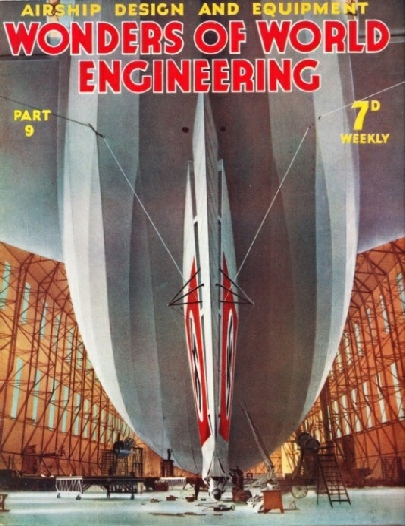

Part 9

Part 9 of Wonders of World Engineering was published on Tuesday 27th April 1937, price 7d.

Part 9 includes a photogravure supplement showing the airship Hindenburg. This illustrates the article on Airship Design and Equipment. The airship is also illustrated in colour on the cover (and see below).

The Cover

This week’s cover shows the giant airship Hindenburg (LZ 129) leaving her enormous hangar at the beginning of one of her voyages to America.

Contents of Part 9

Across the Andes (Part 2)

The story of man’s trials and triumphs in his onslaught on the Andes. The chapter is concluded from part 8. This is the second article in the series on Railway Engineers at Work.

John Smeaton

Well known for his work on the third Eddystone Lighthouse, John Smeaton was engaged at various times on the building of bridges, waterworks, harbours and many other projects. An ardent experimentalist, Smeaton was gifted with unusual aptitude for mechanics. This is the third article in the series on Makers of Engineering History.

X-Rays in Industry

Discovered by Professor W. K. Rontgen in 1895, X-rays are now used for a variety of purposes in industry, from revealing otherwise invisible defects in boiler welds to exposing fakes of old masters. Accidents such as boiler explosions can often be avoided by the timely X-ray examination of structures. For many years we have had cause to be grateful to the X-ray apparatus in medicine, bit few people know of the important service it is beginning to render to industry.

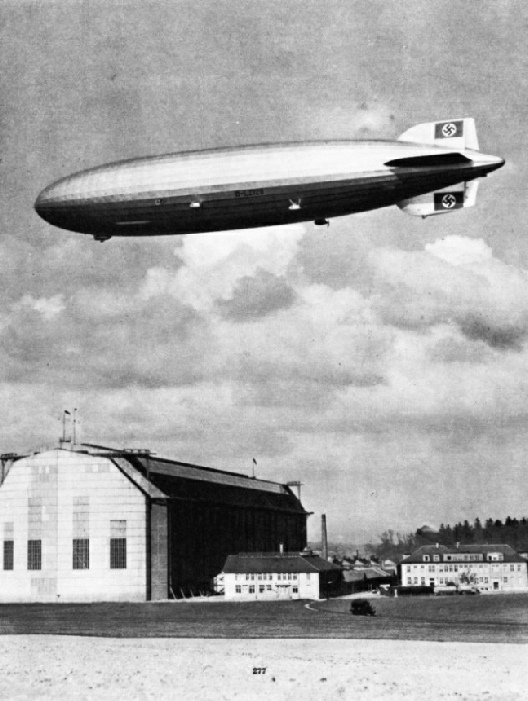

Airship Design and Equipment

The German airship Hindenburg has a maximum gas capacity exceeding 7,000,000 cubic feet, nearly twice that of her predecessor, the Graf Zeppelin. The regularity of the Hindenburg's transatlantic crossings makes her an outstanding example of modern engineering practice. Whatever one’s views may be on the lighter-than-air form, there is no doubt that the airship is not only an established means of long-distance transport, but is also a successful example of modern engineering practice. This chapter gives a comprehensive description of the Hindenburg, and it is accompanied by a superb photogravure section. This chapter is the first in the series Marvels of Modern Transport.

The Hindenburg (photogravure supplement)

Contents of Part 9 (continued)

From Timber to Newsprint

To produce sufficient paper for one edition of a newspaper, nearly a hundred acres of forest must be felled, the timber must be transformed into pulp and the pulp into newsprint or paper by treatment in a number of ingenious machines. This chapter gives some interesting facts about newsprint, or, as it is popularly called, paper. Amazing quantities of it are used. One single edition of one New York Sunday paper - admittedly such editions are larger than those of our own newspapers - alone needs for its production the closely packed trees of nearly one hundred acres of forest. This chapter is the first article in the series on The Romance of Industry.

Conquest of the Desert (Part 1)

Hundreds of thousands of acres of land in the Sudan have been reclaimed from the desert and irrigated by the building of the Sennar Dam across the Blue Nile. The chapter is concluded in part 10. It is the fourth article in the series on Triumphs of Irrigation.

The Hindenburg: Photogravure

Supplement - 2

THE PILOT'S CABIN of the Hindenburg projects beneath the hull of the airship and is 30 feet long, with a maximum width of 8 feet in the centre. The cabin contains the wheelhouse, the map and navigation room, and the direction-finding room.

The Hindenburg: Photogravure

Supplement

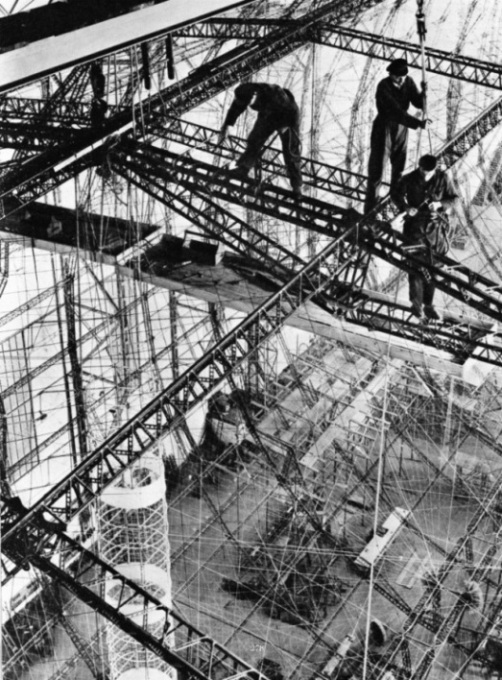

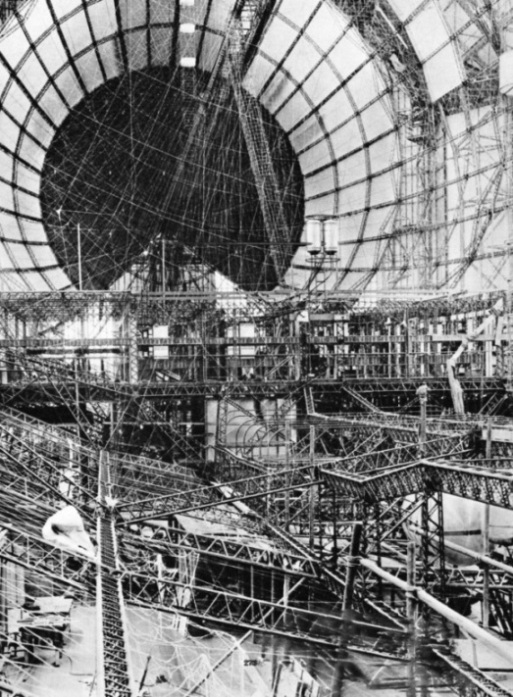

FIFTEEN MAIN RINGS divide the hull into sixteen compartments which hold the gas-bags. The keel longitudinals run almost the whole length of the ship. The envelope fabric is of lightweight linen and cotton, treated with several coatings of cellon, or ‘dope’.

The Hindenburg: Photogravure

Supplement - 3

THE COMPLETED AIRSHIP LZ 129, named Hindenburg. Her overall length is 803 feet and her maximum diameter 135 feet. She has a maximum gas capacity of more than 7,000,000 cubic feet of hydrogen Her maximum width is 153 feet.