© Wonders of World Engineering 2014-

Part 10

Part 10 of Wonders of World Engineering was published on Tuesday 4th May 1937, price 7d.

Part 10 includes a colour plate showing A Streamlined Giant of the Canadian National Railways illustrating the article on Canada’s Streamlined Engines.

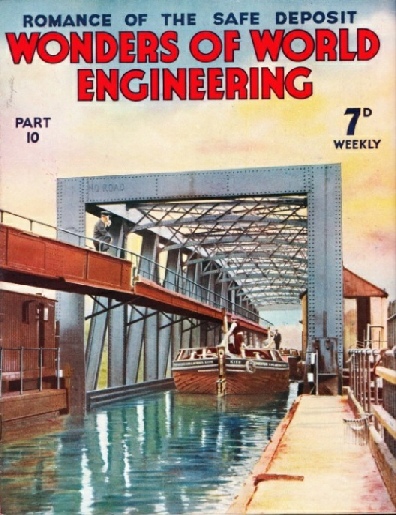

The Cover

This week’s cover shows the unique Barton Aqueduct, which carries the Bridgewater Canal across the Manchester Ship Canal on a swing bridge. How this remarkable arrangement works is described in the chapter on the Manchester Ship Canal.

The Manchester Ship Canal is also described in Shipping Wonders of the World.

Contents of Part 10

Conquest of the Desert (Part 2)

The story of irrigation in the Sudan by the building of the Sennar Dam across the Blue Nile. This is concluded from part 9. It is the fourth article in the series on Triumphs of Irrigation.

James Nasmyth

A brilliant and successful engineer, Nasmyth contributed much to the development of engineering practice, and was the inventor of the steam hammer. This appliance revolutionized the methods of forging and made possible the making of forgings of a size previously thought impracticable. This is the fourth article in the series Makers of Engineering History.

Romance of the Safe Deposit

The design of vaults and strong rooms to withstand earthquakes, fire, explosion, or the scientific methods of burglary has demanded all the skill and ingenuity of the engineer. This chapter describes the evolution and design of the safe deposit.

Canada’s Streamlined Engines

To meet the constantly increasing demands for higher speeds and heavier trainloads, the Canadian National Railways have recently built five streamlined locomotives of enormous size. No. 6400 of the CNR and others of her class weigh, with tender, in working order, 296 tons each. This chapter describes locomotive No. 6400 and her sisters, which differ widely from other engines on the Canadian National system. This article is the second in the series on the Marvels of Modern Transport.

A Streamlined Giant (colour plate)

A Streamlined Giant

A STREAMLINED GIANT. No. 6401, of the Canadian National Railways, is one of a new class of single-expansion passenger express locomotives which appeared in 1936. The engine has eight coupled wheels and leading and trailing bogies, giving her the 4-8-4 wheel arrangement. The two cylinders have a diameter of 24 in and a stroke of 30in. The driving wheels are of 6 ft 5 in diameter. The diameter of the boiler barrle tapers from 7 ft 2 in to 6 ft 6 in. The working pressure is 275 lb per square inch. Tractive effort at 85 per cent boiler pressure is 52,450 lb. The grate area is 74 square feet; mechanical firing is provided. The tender is carried on twelve wheels: its capacity is 11,700 gallons of water and 20 tons of coal. The total weight of engine and tender, in working order, is 296 tons.

Contents of Part 10 (continued)

Handling 2,000,000 Tons of Coal

Every year some two million tons of coal are discharged from colliers at Beckton Gasworks, London, and 250,000 tons are kept in reserve. The largest plant of its kind in the world handles, grades, crushes and delivers the coal to coke ovens and retorts. The plant deals also with the coke that is formed from the coal.

Britain’s Biggest Ship Canal (Part 1)

By its conversion of a great inland city into a seaport the Manchester Ship Canal is an outstanding example of the influence of the engineer’s work on the lives of others. After innumerable difficulties and destructive floods the canal was opened in 1894.

This chapter is concluded in part 11.