© Wonders of World Engineering 2014-

Part 40

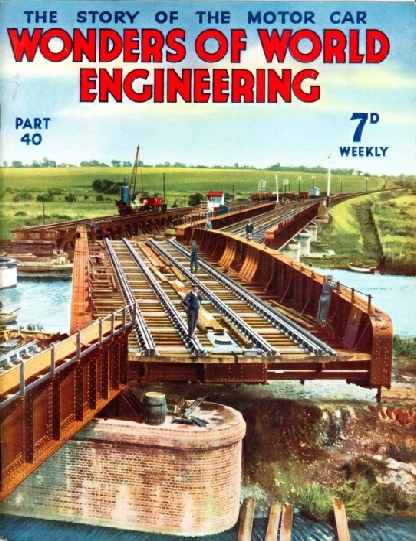

Part 40 of Wonders of World Engineering was published on Tuesday 30th November 1937, price 7d.

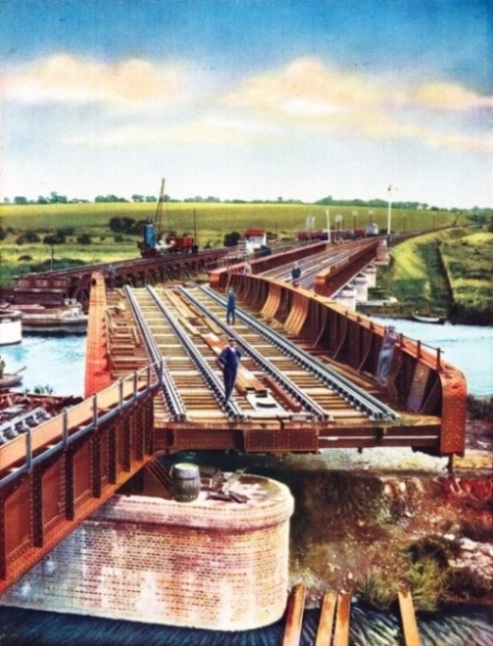

Part 40 includes a colour plate showing a swing bridge on the Ipswich to Yarmouth branch of the London & North Eastern Railway. It formed part of the article on Movable Bridges.

The Cover

The cover of this week’s Part illustrates the work of the engineer in the rebuilding of British railways. It shows a swing bridge, on the Ipswich toYarmouth branch of the London and North Eastern Railway, across the River Waveney at Beccles, Suffolk. The old structure, built in the late ‘fifties, was hand-operated and carried a single line only. Present-day traffic demands two lines and quicker handling, so a heavier swing span, electrically operated from a signal-box at the south abutment, has been installed. The swing span is 136 feet long and rotates on a large turntable provided with rollers. The swinging is effected through gearing by a 30 horse-power electric motor.

Contents of Part 40

Movable Bridges

Many types of rolling, bascule, swing and vertical-lift bridges are in use to-day. Their principles have evolved from early types of movable bridges such as the medieval drawbridge. An attractive colour plate accompanies this informative chapter on various types of movable bridges. From time to time Wonders of World Engineering has included, in the popular series “Linking the World’s Highways”, descriptions of the building of certain movable bridges, such as the Tower Bridge and the swing bridge at Kincardine-on-Forth . This chapter, however, deals with the development of the various forms of movable bridges such as the bascule bridge, the swing bridge, the rolling or retractable bridge and the vertical lift bridge.

Harnessing the Mississippi

There are no great falls of water in the Mississippi, but engineers have been able to use its immense flow to rive thirty huge turbines with an aggregate output of 300,000 horse-power, at Keokuk, Iowa. In the majority of hydro-electric schemes a high head of water is generally necessary to operate the turbines which generate electricity. Until about thirty years ago, therefore, hydro-electric power stations were built only in places where natural conditions provided a sudden and deep fall in a stream. This chapter describes the installation of the first power plant using a comparatively low head of water. This article is the sixth in the series Wonders of Water Power.

The Marsh Buggy

ONE of the most ingenious vehicles developed for engineering purposes is the marsh buggy, which is used in the swamp lands of Louisiana, USA. It travels over roads as a motor car, through swamps as a tractor, and in the water as a boat.

This is the twenty-first article in the series Modern Engineering Practice.

Boilers in the Making

Despite the numerous types and sizes of boilers used in modern engineering, most boilers are made by closely related methods. Drums, end plates and tubes are produced with remarkable care, for much depends on the soundness of the boilermaker’s work.

Harbour Works in France

Large-scale harbour engineering has recently been carried out by engineers of the Port of Bordeaux. Ingenious methods have been adopted in building a jetty for transatlantic liners and an unusual type of suction dredger has been built. One of the most interesting feats of this nature was recently completed by French engineers, who built a reinforced concrete landing jetty at Le Verdon, in the estuary of the River Gironde, sixty miles below Bordeaux. This chapter describes this and other remarkable feats of engineering which have recently been carried out in the Port of Bordeaux.

Development in the 1890s

Motoring had been demonstrated as a practical possibility as early as 1890, but not until 1900 was the motor car a serious challenger in the world of mechanical transport. The period of experiment then gave place to the period of improvement.

This chapter is the second article in the series on the Story of the Motor Car.

Military Engineering (Part 1)

The duties of the Corps of Royal Engineers are not confined to bridge building, roadmaking, railway construction and the demolition of existing buildings. Other activities of the Corps include surveying, mapping, camouflage, anti-aircraft organizations and the postal services of an army in the field. Railway building, bridge building and demolition all come within the scope of military engineering. This chapter on military engineering covers every activity of the famous corps. The article is concluded in part 41.

Swing Bridge Across the River Waveney

SWING BRIDGE across the River Waveney, at Beccles, Suffolk. It carries the Ipswich-Yarmouth line of the LNER. The swing span is electrically operated from a signal box at the south abutment. The span is 136 feet long and rotates on a large turntable provided with rollers. The swinging is effected through gearing by a 30 horse-power electric motor.