© Wonders of World Engineering 2014-

Part 20

Part 20 of Wonders of World Engineering was published on Tuesday 13th July 1937, price 7d.

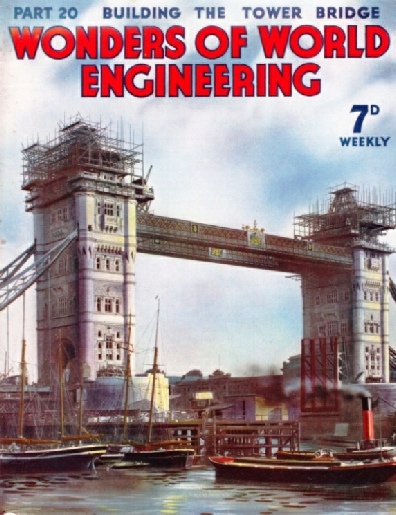

Part 20 includes a colour plate showing Tower Bridge under Construction. It formed part of the article on Building the Tower Bridge. The colour plate was also used as the cover design for this part.

The Cover

The cover this week shows the Tower Bridge in course of construction.

Contents of Part 20

Moscow’s Great Canal (Part 2)

The construction of the canal which links the River Volga with the Moskva River. This chapter is concluded from part 19.

Building the Tower Bridge

The most famous example of the bascule bridge is the Tower Bridge across the River Thames in the heart of London. Engineers were able to build this type of bridge without interrupting traffic on the great commercial waterway. This bridge is one of the most distinctive bridges in London, if not the world, and its construction was a fine achievement. This chapter is the seventh article in the series on Linking the World’s Highways.

The Tower Bridge (colour plate)

Contents of Part 20 (continued)

Sending Pictures by Wire

Some of the finest achievements in the field of electrical engineering are incorporated in the picture telegraphy service which is in regular operation between London and the principal European countries. The General Post Office uses what is known as the Siemens-Karolus system , and a regular service was inaugurated in 1930. This chapter describes how pictures can be transmitted by this system.

Origin of the Steam Engine

Although steam had long been recognized as a potential source of power it was not until the seventeenth and eighteenth centuries that such men as Savery, Newcomen and Watt evolved the principles of the engines now in universal use. Internal combustion engines, such as diesel engines, are becoming increasingly important as motive forces for many forms of transport, but there is little doubt that these newly developed forms of power will never entirely supersede steam.

Hong Kong’s Water Supply

Nearly 400,000 people live on the island of Hong Kong, where the natural water is insufficient for their needs. On the mainland of Kowloon were built a large dam and reservoir to store an adequate supply, which is carried across to the island in a main. In Hong Kong, although there are periodical torrential rains, the natural water supply is insufficient for the 400,000 inhabitants. How the problem was solved is described in this chapter.

Emergency Generating Set

OF the thousand and one tasks the engineer is set to perform, one, unthought of comparatively few years ago, is that of ensuring the continuity of colour light signalling which is now so familiar a sight on railways. With the old semaphore system lighted at night by oil lamps, a breakdown of any signal caused only a local disturbance, but a current failure when electric colour signals are used might paralyse a whole area. The railways, therefore, have emergency generating sets at strategic points. One of these sets is described in this chapter. This is the eleventh article in the series on Modern Engineering Practice.

Conquest of the Severn (Part 1)

The building of the tunnel beneath the River Severn is one of the epics of engineering. For nearly fourteen years men worked on an underwater short cut between England and South Wales, waging a perpetual battle against inundation. The chapter is concluded in part 21 and is the fifth article in the series Below the Surface.