© Wonders of World Engineering 2014-

Part 31

Part 31 of Wonders of World Engineering was published on Tuesday 28th September 1937, price 7d.

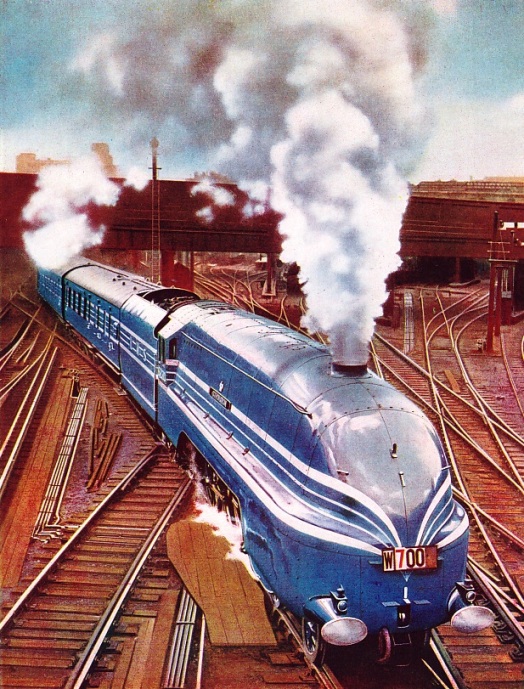

Part 31 includes a colour plate showing the “Coronation Scot” leaving London at the start of the test run on June 29, 1937. It formed part of the article on Britain’s Streamlined Expresses. The colour plate was also reproduced on the cover of this part.

The Cover

The cover of this week’s part shows one of Britain’s latest streamlined trains, “The Coronation Scot”, leaving Euston Station on an experimental run to Crewe, before being put into regular service. On this occasion, a speed of nearly 114 miles and hour was attained.

An article on Britain’s Streamlined Expresses appears in this part.

Contents of Part 31

First Transcontinental Telephone Line (Part 2)

The story of the construction of the first telephone line across America. The article is concluded from part 30.

The Tunkhannock Viaduct

In an extensive scheme of reconstruction, the Pennsylvania, USA, between 1904 and 1914, a daring step was taken when it was decided to use concrete for most of the work. Tunkhannock Viaduct is claimed to be the largest concrete viaduct in the world.

Britain’s Streamlined Expresses

A new chapter in British railway history was written in the summer of 1937, when streamlined express trains began to run between England and Scotland. The LNER express “Coronation” reached Edinburgh in six hours from King’s Cross; by the “Coronation Scot” of the LMS, Glasgow was put within six and a half hours of Euston.

The “Coronation Scot” Leaving London (colour plate)

Contents of Part 31 (continued)

International Exchange

Telephonic communication is now possible between London and almost every country in the world. A vast network of wore and radio links is controlled from Faraday Building, London, which has become the nerve-centre of world communication. In this Exchange all telephone calls from Great Britain to countries abroad and overseas are dealt with. Ingenious electrical mechanism records the length of telephone conversations, automatically deducting the lengths of periods in which conversation is interrupted for any reason.

Lord Armstrong

Although at first he had practised law, William George Armstrong, who became a peer in 1887, was always interested in engineering. His first success was in the field of hydraulic power transmission and he invented the hydraulic accumulator. His later activities extended to the designing and making of ordnance. This is the eleventh article in the series on Makers of Engineering History.

Diamonds and the Engineer (Part 1)

Apart from their intrinsic value as precious stones, diamonds are of almost inestimable worth to the engineer, for they are indestructible and will cut their way through the toughest steel and the hardest stone or rock. This chapter describes the remarkable ways in which diamonds are used in engineering. Diamonds are used for hardness testing machines, which test the degree of hardness of metal parts which are subject to wear and tear or stress, for cutting glass and porcelain, for fine engraving, for dressing emery wheels, and for many other purposes. This chapter also describes diamond mining in South Africa. The article is concluded in part 32.

The “Coronation Scot” Leaving London

AT THE START OF THE TEST RUN on June 29, 1937, “The Coronation Scot” leaving London. The engine is No. 6220 Coronation, the first of the five streamlined Pacifics built in 1937 for the haulage of high-speed trains on the LMS. On the test run Coronation, with 270 tons gross behind the tender, ran from Euston to Crewe, 158.1 miles, in 2 hours 9 minutes 46 seconds, at an average speed of 73.1 miles an hour. The return journey was completed in an overall time of 1 hour 59 minutes from start to stop. These times were respectively 5¼ and 16 minutes ahead of the special schedule of 2¼ hours. In the summer of 1937 “The Coronation Scot” was booked to cover the distance in 2 hours 24 minutes in either direction in the course of its non-stop runs between Euston and Carlisle.