© Wonders of World Engineering 2014-

Part 30

Part 30 of Wonders of World Engineering was published on Tuesday 21st September 1937, price 7d.

Part 30 includes a photogravure supplement showing the motorways of Germany, which illustrates the article on the Motorways of Germany.

The Cover

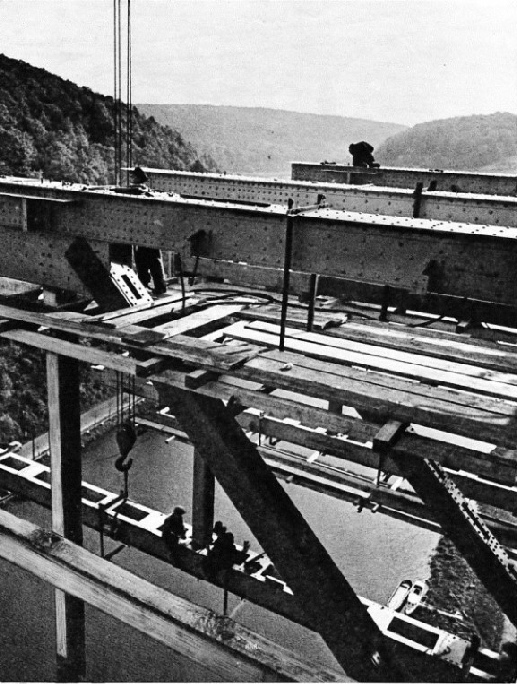

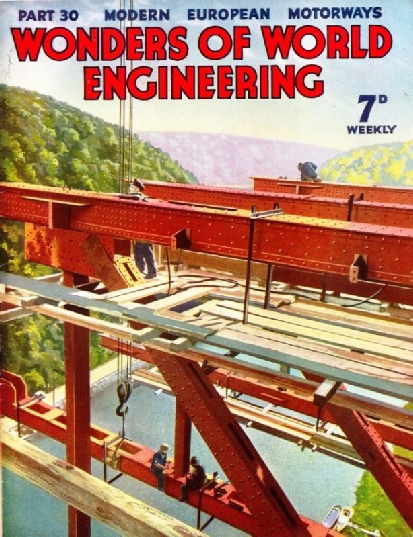

This week’s cover is reproduced as a photogravure illustration to the chapter entitled Motorways of Germany. The picture shows the erection of steel girders for the bridge which carries one of these great new roads across the River Werra.

Contents of Part 30

A Canal Through a Mountain (Part 2)

The story of the canal between the port of Marseilles and the River Rhone, and the construction of a tunnel four and a half miles long driven beneath a range of rocky heights. This chapter is the eighth article in the series Below the Surface. The article is concluded from part 29.

The Scottish Shale Industry

From the thousands of tons of shale which are mined and reported in Scotland every year, numerous products are extracted, including such valuable commodities as motor spirit, naptha, paraffin wax and ammonium sulphate. Shale is mined in the same way as coal.

Motorways of Germany

Nearly 1,000 miles of great new express motorways, or Autobahnen, as they are called, have in recent years been built in Germany. Ingenious flying and burrowing junctions have been built to assist the flow of traffic. This chapter describes how the great German motorways are changing the face of the land. The scheme involves many major engineering works, such as the building of bridges and viaducts, the excavation of cuttings and the making of embankments.

Motorways of Germany (photogravure supplement)

Motorways of Germany

Photogravure Supplement - 3

ACROSS THE RIVER WERRA, near Eisenach, in central Germany, a high steel-girder bridge carries the Autobahn. The photograph shows one of the massive girders being placed in position.

This illustration was reproduced in colour for the cover of this part.

Motorways of Germany

Photogravure Supplement - 2

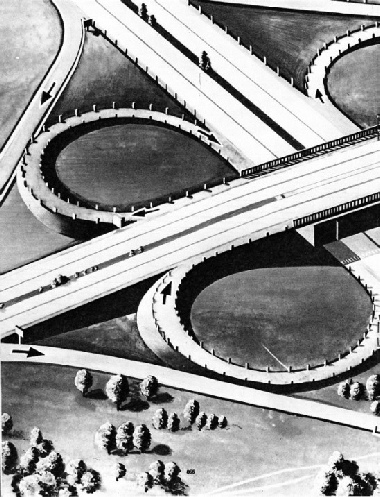

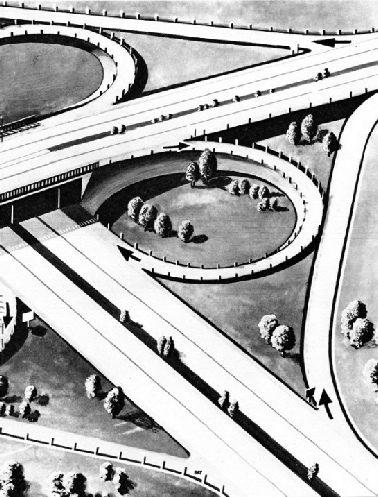

FOUR-WAYS INTERSECTIONS on the German Autobahn system have been designed so that no two streams of traffic have to meet or cross at any point on the same plane. The drawing shows a typical intersection. The direct east-west route is carried over the north-south route by a viaduct. From the approaches to the viaduct, spur roads lead down to join the north-south route. Traffic in Germany travels on the right-hand side of the highway, so that these spur roads provide only for right-hand turns. When it is desired to turn to the left, vehicles on, say, the north-south road pass under the elevated road, then turn right into a curved spur road which leads round, through three-quarters of a circle, up to the east-west road; the vehicles thus join the new route in the same direction as the east-west or west-east traffic. Similar curved spur roads are provided for traffic on the east-west route which desires to make a left-hand turn on to the lower, or north-south route.

Motorways of Germany

Photogravure Supplement

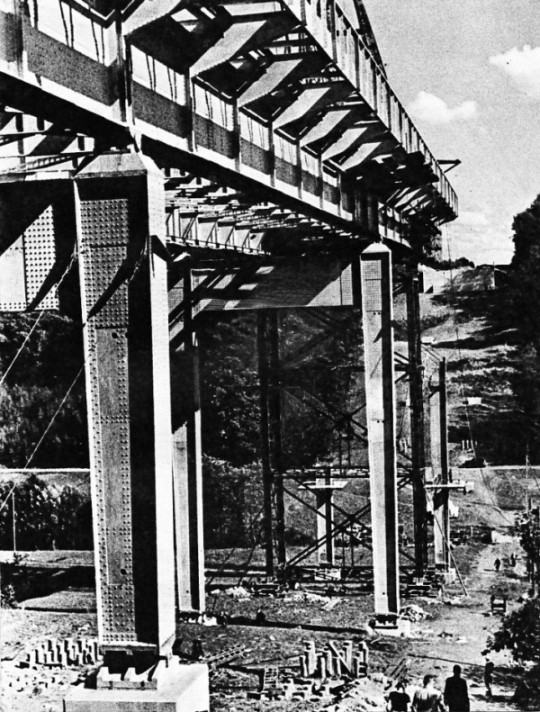

MASSIVE STEEL GIRDERS carry the dual carriageways of the German Autobahnen across valleys and low-lying country, to eliminate detours and to afford more direct routes for long-distance motor transport. It is calculated that the the cost of these bridges and viaducts is amply covered by the saving of fuel which would otherwise be wasted by deviations from the direct route.

Contents of Part 30 (continued)

Story of the Boiler

This chapter describes how the numerous types of boiler in use to-day have developed on the principles outlined by such inventors as Trevithick and James Watt. This chapter begins the new series because many readers have written and suggested a chapter which would carefully explain the principle of the various types of marine and land boilers in use to-day. It is the first chapter in this new series Invention and Development.

Electro-Plating Plant

Few owners of bicycles are probably aware that the plating of a bicycle’s bright parts may have involved the use of machines perhaps 100 feet in length and having elaborate automatic handling mechanisms. This chapter describes a chromium-plating machine of comparatively small size. This is the eighteenth article in the series on Modern Engineering Practice.

The First Transcontinental Telephone Line

The first telephone line across America was opened by Graham Bell, the inventor of the telephone, in 1915, when he conversed with San Francisco from New York. Engineers had to carry the pioneer lines over prairie, desert, swamp and mountain ranges. One of the great landmarks in the history of the telephone was the building of the first transcontinental telephone line, between new York and San Francisco, a distance of about 3,400 miles. The article is concluded in part 31.