© Wonders of World Engineering 2014-

Part 33

Part 33 of Wonders of World Engineering was published on Tuesday 12th October 1937, price 7d.

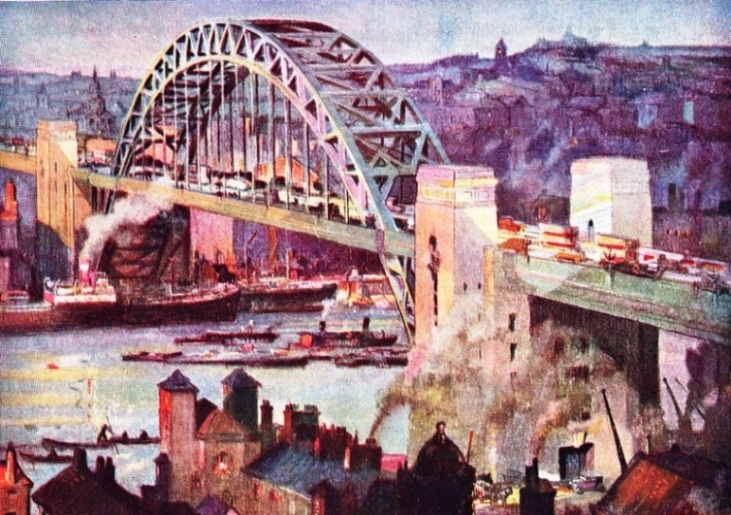

Part 33 includes a colour plate showing the new Tyne Bridge at Newcastle. It formed part of the article on Bridges Across the Tyne.

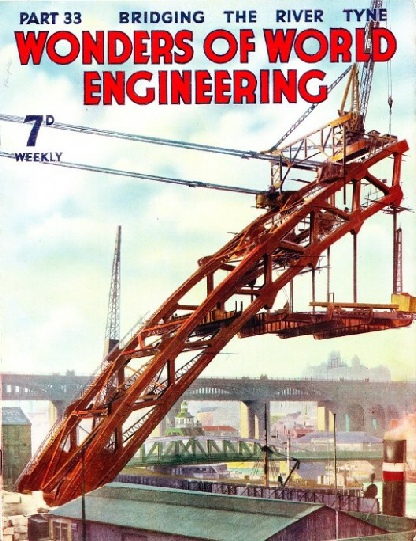

The Cover

This week’s cover picture, reproduced by courtesy of Dorman Long & Co Ltd, shows part of the arch of the New Tyne Bridge at Newcastle, during construction. The procedure adopted in building this bridge was the same as that used in the construction of Sydney harbour bridge - the tow half-arches were built out simultaneously and anchored back by great steel cables, some of which are shown in the cover illustration.

Contents of Part 33

Story of the Cinematograph - 1 (Part 2)

The story of the development of one of the largest industries in the world, concluded from part 32. This is the second article in the series Invention and Development.

Bridges Across the Tyne

A remarkable group of bridges in or near Newcastle carries the traffic across the River Tyne. The most recent of these is the largest single-arch bridge in Great Britain. This chapter on Newcastle’s bridges across the Tyne describes five different bridges, which are crowded into a distance of less than one mile. One of these bridges carries the London and North Eastern Railway across the Tyne on its way to Scotland. The most recent - Tyne Bridge - was opened by King George V on October 10, 1928. This bridge is the subject of a colour plate (shown below). The article is the eleventh in the series on Linking the World’s Highways.

The New Tyne Bridge (colour plate)

The New Tyne Bridge

Rising to a height of 200 feet above the river, the single-arch span of the Tyne Bridge at Newcastle is the largest in Great Britain. The approach spans carry the road over the streets and houses, giving the bridge a total length of 1,254 feet. The roadway is 38 feet wide and there are 9-feet footways on either side. The great steel arch has a span of 531 feet. The Tyne Bridge was opened by His Majesty King George V on October 10, 1928.

Contents of Part 33 (continued)

Ball and Roller Bearings

The bearings in which moving parts of machinery are supported have to withstand many different kinds of stress. The utmost care, therefore, has to be taken in the manufacture of these vital components. The ball bearing is a small component which has probably done more to reduce friction and wear and tear in machinery than anything else. This chapter describes the many fascinating processes used in the manufacture of ball and roller bearings. This is the eleventh article in the series on the Romance of Industry.

Motor Railcar

As the steam locomotive goes flashing by it flaunts its coupling rods, and also its connecting rods, if it has outside cylinders. The axles are driven by these long shining rods, but in the motor railcar there is nothing to indicate what drives the wheels. This article describes one of the latest LMS railcars. This is the nineteenth article in the series on Modern Engineering Practice.

Marine Engines and Steamships

In the century which followed William Symington’s first application of a steam engine for driving a vessel’s paddle wheels enormous advances were made, not only in ship design but also in marine engineering. The development of the marine engine has made possible the vast ocean liners of to-day. The steam reciprocating engine brought about a revolution in marine transport during the nineteenth century, and the story of its development is described in this chapter. This is the third article in the series Invention and Development.

Unit Construction

Simplicity of design is a modern tendency of engineering in practice. Such structures as aircraft hangars and bridges can now be efficiently and economically built from sections or units of a standard pattern. Engineering practice to-day tends towards simplicity of design, so that structures of all kinds may be quickly built up. This is particularly true of the building industry, and this chapter deals with the use of unit construction in engineering.

Canada’s Mineral Wealth (Part 1)

The production of metal in Canada has increased in recent years to such an extent that mineral production in the Dominion is now second only to agriculture among the primary industries. This chapter describes how Nature has been conquered by the use of aircraft, tractors, marine railways to by-pass rapids, power navigation of the vast inland waterways, radio and the most advanced types of mining equipment. Nowadays mineral production in Canada is second only to agriculture, thanks to the work of the engineer. This article is concluded in part 34.