© Wonders of World Engineering 2014-

Part 25

Part 25 of Wonders of World Engineering was published on Tuesday 17th August 1937, price 7d.

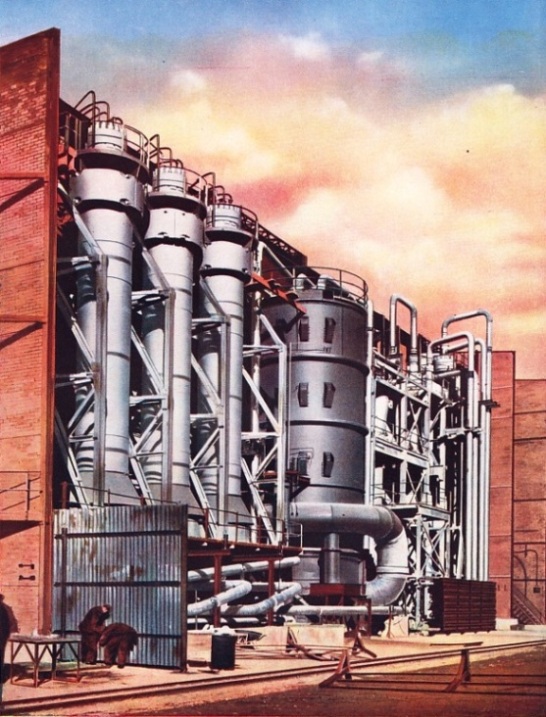

Part 25 includes a colour plate showing converters used in the hydrogenation of coal. It formed part of the article on Petrol from Coal. The colour plate was also used as the cover design for this part.

The Cover

The cover of this week’s Part is reproduced as a colour plate. Made from a photograph supplied by Imperial Chemical Industries Limited, the cover shows the high-pressure vessels known as converters, at Billingham, Co. Durham. In these huge forged steel vessels coal is hydrogenated to effect the extraction of oil, as described in the chapter Petrol from Coal.

Contents of Part 25

Reclaiming the Pontine Marshes (Part 2)

The great work of the reclamation of the Pontine Marshes, by C Hamilton Ellis. This chapter is concluded from part 24.

Central Telegraph Office

An entirely new technique for handling telegrams has been devised and perfected in recent years to ensure the highest possible speed and accuracy at every stage in their dispatch and delivery. This chapterdescribes the Central Telegraph Office in London. As recently as 1929 there were five types of telegraphy in use, but now all these systems have been superseded for inland work by the teleprinter, an ingenious machine which is described in this chapter.

Southern Railway Express 4-6-0

The largest Southern Railway 4-6-0s are four-cylinder simple engines of the Lord Nelson class, named after famous admirals. No. 850 Lord Nelson, which appeared in 1926, was followed by fifteen similar locomotives, numbered 851-865. In 1937 No. 857 Lord Howe - described in this chapter - was rebuilt with an enlarged boiler having a round-topped firebox. This is the fifteenth article in the series on Modern Engineering Practice.

Water for Western Australia

It was not until January 1903 that Kalgoorlie had a regular water supply, derived from a range of mountains about 350 miles away from the town. A reservoir was formed by building a huge concrete overflow weir across the Helena River. The water, which was pumped through what was formerly wilderness, now maintains farms, towns and mines hundreds of miles away from the source of supply. This achievement ranks among the most remarkable in the history of Australian engineering, and is described in this chapter. This is the seventh article in the series on Triumphs of Irrigation.

High-Pressure Vessels (colour plate)

Contents of Part 25 (continued)

Petrol from Coal

The extraction of petrol from coal by the hydrogenation process requires extremely high temperatures and pressures. The enormous plant at Billingham, Co. Durham, is the outcome of years of intensive research in this new and important industry. At Billingham petrol is extracted from the coal by what is known as the hydrogenation process. It is a remarkable process, and is carried out in extremely high pressures and temperatures. The process is described in this chapter. This is the seventh article in the series on the Romance of Industry.

Modern Engineering Research

Investigations of great importance are carried out at the National Physical Laboratory at Teddington, Middlesex. The Engineering Department of the National Physical Laboratory frequently investigates the properties of materials for unusual conditions, and this chapter describes the ways in which strength of metals is measured, and also how many other important investigations and tests are carried out. The work of the Engineering Department is extremely varied, and during 1936, for instance, some thirty-seven important items of research were in active progress, including experiments to determine the effect of wind pressure on buildings and bridges and the effect of wheel impact on roads and vehicles.

Prospecting From the Air (Part 1)

Information otherwise inaccessible to mining engineers can be obtained by the use of aircraft for surveying, and amazingly accurate deductions can now be made from a co-ordinated series of aerial photographs. Aerial photography and surveying is particularly useful for mining engineers who wish to develop a promising area, and this chapter describes how aerial surveys are carried out in specially equipped machines, with particular reference to the value of aircraft to mining engineers. The article is concluded in part 26.