© Wonders of World Engineering 2014-

Part 13

Part 13 of Wonders of World Engineering was published on Tuesday 25th May 1937, price 7d.

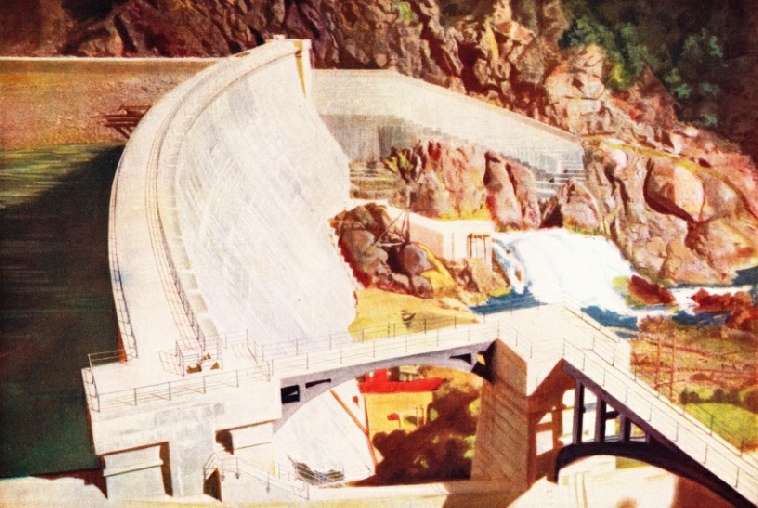

Part 13 includes a colour plate showing the Burrinjack Dam, New South Wales. It formed part of the article on Fighting the Drought Menace.

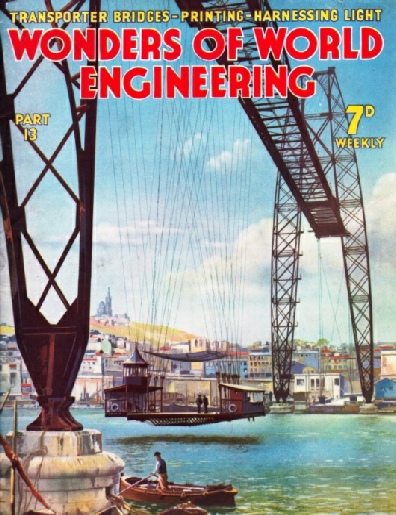

The Cover

The cover this week shows the Transporter Bridge over the Old Harbour of Marseilles. This structure, which is described in the chapter entitled Transporter Bridges, is one of the biggest landmarks in the famous French seaport.

Contents of Part 13

The Modern Coal Mine (Part 2)

The marvellous improvements which are now used to aid the miner in his work and to minimize the danger in which he toils. This chapter is concluded from part 12.

Electricity in the Heart of Africa

One of the biggest feats of engineering in Africa in recent years was the building of the Benguela Railway, from the port of Lobito across Angola to the Belgian Congo and Northern Rhodesia. The railway was built with British material and British capital. At Nova Lisboa are huge railway repair shops, for which power is derived from the hydro-electric plant at the Cuando River Falls a few miles away.

Transporter Bridges

The most practicable and economical way to carry road traffic across a waterway is often by a transporter bridge. No approach viaducts are necessary, although the permanent span is at such a height as to give plenty of headway for shipping. River traffic is interrupted only by the crossing of the suspended transporter car. There are not a great many examples, because the design is for particular conditions which do not apply everywhere there is a need for a bridge. One of the best known of transporter bridges is the one at Runcorn, Cheshire, and there are some famous examples in France, at Marseilles and at Rouen, for instance.

Harnessing Light

The principle of control by the photoelectric cell has unlimited applications in the field of engineering. In an amazing variety of ways the cell is a safeguard in industry and an invaluable part of the engineer’s equipment. Among the many discoveries of science is the photoelectric cell which has now been applied to so many things in our everyday life - as, for instance, in traffic-actuated signals . Many remarkable adaptations of the photoelectric cell principle have been made by the engineer and this chapter explains how the photoelectric cell has affected various forms of engineering.

Magazines by the Million

The many processes involved in the production of millions of copies of a periodical - such as typesetting, printing, folding, binding and trimming - are carried out by machines which work at remarkable speeds and with extreme precision. When you open your copy of Wonders of World Engineering you do so only because industrial engineers have perfected over scores of years huge machines which cast the metal type, set it, and make it possible for hundreds of copies an hour to be made. This chapter is the second article in the series on the Romance of Industry.

Plano-Milling Machine

The number of different kinds of machine tools in daily use and the huge dimensions that some of them have now attained are surprising. An example is described in this chapter of a large plano-milling machine at work on the machining of part of a diesel engine bedplate. The machine is an ingenious combination of two older forms of tool, the planing machine and the milling machine. This is the sixth article in the series on Modern Engineering Practice.

Fighting the Drought Menace (Part 1)

To combat drought, the Australian farmer’s greatest enemy, mighty barrages have been built and thousands of miles of canals dug. Work has entailed stern battles against the forces of Nature in mountainous country far from civilization. This chapter deals with many of the irrigation schemes in Australia, and describes the building of the huge Burrinjuck Dam in a remote district of New South Wales. The article is concluded in part 14. It is the fifth part in the series on Triumphs of Irrigation.

The Burrinjack Dam (colour plate)

The Burrinjuck Dam

BURRINJUCK DAM (above) was built across a gorge of the Murrumbidgee River, New South Wales, just below its confluence with the Goodradigbee River. The dam is 236 feet high, with a width of 168 feet at the base, tapering to 18 feet at the top. The crest of the dam is 780 feet long. There is a spillway on either side of the dam to carry off overflow water, in addition to four 4½ feet valve openings in the base of the dam. The dam, which was completed in 1914, has formed a reservoir with a water surface area of 12,780 acres, with a maximum depth of 200 feet.